Picture this: It’s 2:30 AM on a Tuesday, and your production floor supervisor is frantically calling you. The entire assembly line has ground to a halt because the manufacturing execution system (MES) crashed. Workers are standing idle, machines are silent, and every minute of downtime is costing your company thousands of dollars. Sound familiar?

If you’re in manufacturing, you’ve probably lived this nightmare more than once. In today’s hyper-connected industrial landscape, your IT infrastructure isn’t just supporting your business – it IS your business. When technology fails, production stops, quality suffers, and profits evaporate faster than you can say “system reboot.”

Key Takeaways

- IT downtime directly translates to production losses, with manufacturing companies losing an average of $50,000 per hour during unplanned outages

- Legacy systems and poor integration create bottlenecks that slow down entire assembly lines and compromise data accuracy

- Proactive IT management and modern solutions like ACIS Manufacturing can prevent costly disruptions and optimize production efficiency

- Real-time monitoring and predictive maintenance help identify issues before they cause assembly line shutdowns

- Investing in robust IT infrastructure delivers measurable ROI through increased uptime, improved quality, and reduced operational costs

Ready to Eliminate IT Lag for Good?

ACIS Manufacturing has helped hundreds of manufacturers transform their IT infrastructure and eliminate costly production delays. We understand that when your IT lags, your assembly line does too and we know exactly how to fix it.

Don't wait for the next system failure to force your hand.Take control of your technology destiny and give your assembly line the IT infrastructure it deserves.

📅 Book a Schedule NowThe Domino Effect: How IT Problems Cascade Through Manufacturing

When Systems Fail, Everything Fails

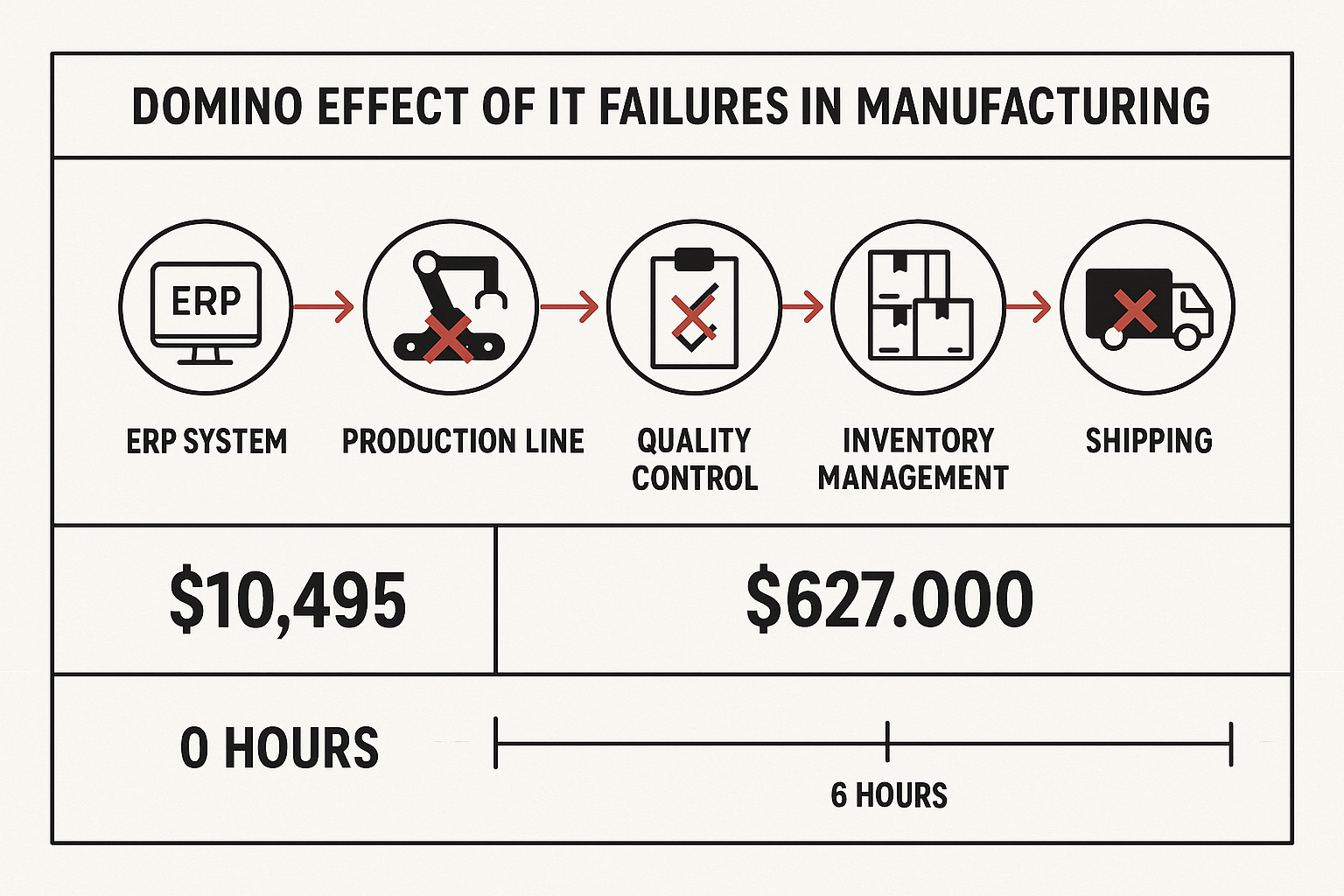

I remember visiting a client’s facility last year, a mid-sized automotive parts manufacturer. They were proud of their state-of-the-art robotic assembly line, but their IT infrastructure was stuck in 2010. During my tour, their enterprise resource planning (ERP) system froze mid-production.

What happened next was like watching dominoes fall:

- Production data stopped flowing to quality control stations

- Inventory tracking became unreliable, causing material shortages

- Scheduling systems couldn’t update, leading to confusion on the floor

- Quality assurance protocols failed, risking defective products reaching customers

The result? A six-hour shutdown that cost them $180,000 in lost production, overtime wages, and rush shipping fees to meet customer deadlines.

The Real Cost of IT Lag in Manufacturing

According to recent industry studies, manufacturing companies experience an average of 800 hours of downtime annually. That’s equivalent to losing an entire month of production every year!

Here’s what IT lag really costs manufacturers:

| Impact Area | Average Cost | Hidden Consequences |

| Production Downtime | $50,000/hour | Lost customer confidence |

| Quality Issues | $25,000/incident | Brand reputation damage |

| Inventory Errors | $15,000/month | Cash flow problems |

| Compliance Failures | $100,000/violation | Regulatory scrutiny |

Challenge 1: Legacy Systems That Can’t Keep Up

The Problem: Outdated Infrastructure

Many manufacturing facilities are running on IT systems that were cutting-edge… in 2005. These legacy systems are like trying to run a Formula 1 race with a horse and buggy. They simply can’t process the volume and complexity of data that modern manufacturing demands.

Common legacy system issues include:

– Slow processing speeds that bottleneck production

– Poor integration between different software platforms

– Security vulnerabilities that expose sensitive data

– Limited real-time reporting capabilities

– Expensive maintenance and limited vendor support

Why It Matters

When your IT lags, your assembly line does too. Legacy systems create artificial speed limits on your production capacity. Even if your machinery can run faster, outdated software becomes the weakest link in your chain.

The Solution: Modernization with ACIS Manufacturing

ACIS Manufacturing offers a comprehensive approach to IT modernization that doesn’t require ripping out your entire infrastructure overnight. Here’s how we tackle legacy system challenges:

- Gradual Migration Strategy: We work with your existing systems while gradually introducing modern components

- Cloud-Based Solutions: Reduce hardware dependency and improve scalability

- API Integration: Connect disparate systems for seamless data flow

- Real-Time Analytics: Transform your data into actionable insights

Challenge 2: Data Silos That Block Production Flow

The Problem: Information Islands

Imagine trying to conduct an orchestra where the violins can’t hear the drums, and the brass section is playing from a different sheet of music. That’s what happens when manufacturing data is trapped in silos.

I’ve seen companies where:

– Production data lives in one system

– Quality metrics are tracked in spreadsheets

– Inventory information exists in a separate database

– Maintenance schedules are managed manually

Why It Matters

When your IT systems can’t talk to each other, your assembly line operates blind. Workers make decisions based on incomplete information, leading to:

– Overproduction of items already in excess

– Quality issues that aren’t caught until it’s too late

– Inventory shortages that stop production mid-cycle

– Unexpected equipment failures due to poor maintenance tracking

The Solution: Integrated Manufacturing Intelligence

ACIS Manufacturing breaks down data silos by creating a unified information ecosystem:

Seamless Integration

– Connect all your manufacturing systems through standardized APIs

– Real-time data synchronization across platforms

– Single source of truth for all production information

Unified Dashboard

– See all critical metrics in one place

– Customizable views for different roles and responsibilities

– Mobile access for floor managers and executives

Automated Workflows

– Trigger actions based on real-time data

– Reduce manual data entry and human error

– Improve response times to production issues

💰 Manufacturing Downtime Cost Calculator

Challenge 3: Reactive Instead of Predictive Maintenance

The Problem: Fighting Fires Instead of Preventing Them

Most manufacturing facilities operate in reactive mode when it comes to IT and equipment maintenance. They wait for something to break before fixing it. This approach is like driving a car until the engine seizes instead of changing the oil regularly.

Reactive maintenance creates a vicious cycle:

- Equipment fails unexpectedly

- Production stops while waiting for repairs

- Emergency repairs cost 3-5x more than planned maintenance

- Stress levels skyrocket as deadlines approach

- The cycle repeats with the next failure

Why It Matters

When your IT lags, your assembly line does too, especially when that lag comes from preventable system failures. Reactive maintenance doesn’t just cost money; it destroys your ability to plan and execute efficiently.

The hidden costs of reactive IT maintenance:

– Lost customer trust due to missed delivery dates

– Employee burnout from constant crisis management

– Inventory waste from production disruptions

– Compliance risks when quality systems fail unexpectedly

The Solution: Predictive Intelligence with ACIS Manufacturing

ACIS Manufacturing transforms your approach from reactive to predictive through:

Predictive Analytics

– Monitor system performance in real-time

– Identify patterns that predict failures before they happen

– Schedule maintenance during planned downtime windows

Smart Alerts

– Receive notifications before problems become crises

– Prioritize issues based on potential impact

– Track resolution times and system health trends

Automated Maintenance Workflows

– Schedule routine maintenance automatically

– Track maintenance history and effectiveness

– Optimize maintenance schedules based on actual usage data

Ready to Stop IT-Related Production Losses?

Don't let technology failures hold your assembly line hostage!

ACIS Manufacturing specializes in creating robust, integrated IT solutions that keep your production running smoothly. Our team of manufacturing technology experts can assess your current systems and design a roadmap to eliminate costly downtime.

📅 Book a Schedule NowChallenge 4: Poor Real-Time Visibility Into Operations

The Problem: Flying Blind on the Production Floor

Imagine trying to drive a car with a blindfold on; that’s what it feels like to manage a modern assembly line without real-time visibility into operations. Many manufacturers are making critical decisions based on yesterday’s data or, worse, gut feelings.

Common visibility gaps include:

– Production metrics that are hours or days behind reality

– Equipment status that requires manual checking

– Inventory levels that don’t reflect actual consumption

– Workforce productivity that can’t be measured accurately

– Quality indicators that only show problems after they’ve spread

Why It Matters

When your IT systems can’t provide real-time insights, your assembly line operates in reactive mode. Problems compound before you even know they exist, and opportunities for optimization slip away unnoticed.

Real-world example: A food processing client was experiencing random quality issues that seemed to appear without warning. After implementing ACIS Manufacturing’s real-time monitoring, we discovered that temperature fluctuations in their storage area were causing ingredient degradation. The issue had been happening for months, but their systems only reported daily averages, not real-time variations.

The Solution: Real-Time Manufacturing Intelligence

ACIS Manufacturing provides comprehensive visibility through:

Live Production Dashboards

– Real-time production rates and efficiency metrics

– Equipment status and performance indicators

– Quality measurements as they happen

– Customizable views for different roles and responsibilities

Intelligent Alerting Systems

– Immediate notifications when metrics fall outside acceptable ranges

– Escalation procedures for critical issues

– Mobile alerts for managers and supervisors

Advanced Analytics

– Trend analysis to identify improvement opportunities

– Predictive modeling for capacity planning

– Root cause analysis tools for problem-solving

Challenge 5: Cybersecurity Vulnerabilities That Threaten Operations

The Problem: Manufacturing Under Attack

Manufacturing facilities have become prime targets for cybercriminals. Unlike traditional IT environments, manufacturing systems often prioritize availability over security, creating vulnerabilities that can shut down entire production lines.

Common cybersecurity risks in manufacturing:

– Industrial control systems with default passwords

– Connected devices without proper security protocols

– Remote access points that bypass security measures

– Legacy systems that can’t be updated with security patches

– Employee devices that connect to production networks

Why It Matters

A successful cyberattack doesn’t just steal data; it can also physically stop your assembly line and cause safety hazards. When your IT security lags, your entire operation becomes vulnerable.

Recent industry statistics:

– Manufacturing accounts for 23% of all cyberattacks globally

– Average cost of a manufacturing cyber incident: $4.2 million

– Average downtime from a cyberattack: 23 days

The Solution: Comprehensive Cybersecurity for Manufacturing

ACIS Manufacturing implements multi-layered security that protects without hindering operations:

Network Segmentation

– Isolate critical production systems from general IT networks

– Control access between different operational zones

– Monitor all network traffic for unusual activity

Advanced Threat Detection

– AI-powered monitoring that learns normal operational patterns

– Real-time threat identification and response

– Automated containment of security incidents

Security Training and Policies

– Employee education on manufacturing-specific security risks

– Clear protocols for handling security incidents

– Regular security assessments and updates

Challenge 6: Scalability Issues That Limit Growth

The Problem: IT Systems That Can’t Grow With Your Business

Success in manufacturing often means increased production demands, new product lines, additional facilities, or expanded markets. But what happens when your IT infrastructure can’t scale to meet these opportunities?

Common scalability bottlenecks:

– Server capacity that maxes out during peak production

– Database limitations that slow down as data volume grows

– Network bandwidth that can’t handle increased traffic

– User licensing that becomes prohibitively expensive

– Geographic limitations that prevent multi-site operations

Why It Matters

When your IT infrastructure can’t scale, it becomes a ceiling on your growth. You might have the market demand and production capacity, but technology limitations force you to turn away opportunities.

I’ve worked with companies that literally had to stop taking orders because their systems couldn’t handle the volume. That’s not just lost revenue, it’s lost competitive advantage and market position.

The Solution: Scalable Architecture with ACIS Manufacturing

ACIS Manufacturing designs systems that grow with your business:

Cloud-Native Solutions

– Automatically scale computing resources based on demand

– Pay only for what you use, when you use it

– Global accessibility for multi-site operations

Modular Design

– Add new capabilities without disrupting existing operations

– Integrate new facilities seamlessly

– Customize solutions for different product lines or markets

Performance Optimization

– Continuous monitoring and tuning of system performance

– Proactive capacity planning based on business projections

– Load balancing to ensure consistent response times

The ROI of Fixing IT Lag in Manufacturing

Measuring the Impact

When you eliminate IT lag in your manufacturing operations, the benefits extend far beyond just avoiding downtime. Here’s what our clients typically see after implementing ACIS Manufacturing solutions:

Quantifiable Improvements:

| Metric | Typical Improvement | Annual Value |

| Unplanned Downtime | 75-85% reduction | $500k – $2M |

| Overall Equipment Effectiveness (OEE) | 15-25% increase | $300K – $1.5M |

| Quality Defects | 40-60% reduction | $200K – $800K |

| Inventory Carrying Costs | 20-30% reduction | $150K – $600K |

| Energy Consumption | 10-15% reduction | $50K – $200K |

Based on mid-sized manufacturing facilities with $50M+ annual revenue

Real Client Success Story

Challenge: A precision machining company was losing $75,000 monthly due to IT-related production delays. Their 15-year-old ERP system couldn’t keep up with modern production demands, causing frequent bottlenecks.

Solution: ACIS Manufacturing implemented a phased modernization approach:

- Month 1-2: Real-time monitoring and alerting systems

- Month 3-4: Integration of production and quality systems

- Month 5-6: Predictive maintenance implementation

- Month 7-8: Complete ERP modernization

Results after 12 months:

– 92% reduction in IT-related downtime

– $850,000 increase in annual production value

– 45% improvement in on-time delivery

– ROI of 340% in the first year

Implementing Change: A Practical Roadmap

Phase 1: Assessment and Planning (Weeks 1-4)

Current State Analysis

– Comprehensive audit of existing IT infrastructure

– Identification of critical bottlenecks and vulnerabilities

– Documentation of current costs related to IT lag

Requirements Gathering

– Stakeholder interviews across all departments

– Production workflow analysis

– Future growth projections and scalability needs

Roadmap Development

– Prioritized list of improvements based on impact and effort

– Timeline and budget estimates

– Risk assessment and mitigation strategies

Phase 2: Quick Wins (Weeks 5-12)

Immediate Improvements

– Implementation of real-time monitoring for critical systems

– Basic integration between disconnected systems

– Emergency backup and recovery procedures

Enhanced Visibility

– Production dashboard deployment

– Automated alerting for key performance indicators

– Mobile access for floor managers

Phase 3: Core System Modernization (Months 4-8)

Infrastructure Upgrades

– Server and network capacity improvements

– Cloud migration for appropriate systems

– Security enhancements and compliance measures

System Integration

– API development for seamless data flow

– Workflow automation implementation

– Data warehouse and analytics platform deployment

Phase 4: Advanced Optimization (Months 9-12)

AI and Machine Learning

– Predictive maintenance algorithms

– Quality prediction models

– Demand forecasting improvements

Continuous Improvement

– Performance optimization based on real-world usage

– Additional feature development

– Staff training and change management

Choosing the Right Technology Partner

What to Look for in a Manufacturing IT Partner

Not all technology providers understand the unique challenges of manufacturing. When your IT lags, your assembly line does too, so you need a partner who gets the urgency and complexity of industrial operations.

Manufacturing Expertise

– Deep understanding of production workflows

– Experience with industrial protocols and standards

– Knowledge of regulatory requirements (FDA, ISO, etc.)

Technical Capabilities

– Proven track record with system integration

– Cloud and on-premise hybrid solutions

– Cybersecurity expertise specific to manufacturing

Partnership Approach

– Collaborative planning and implementation

– Ongoing support and optimization

– Transparent communication and reporting

Why ACIS Manufacturing Stands Out

ACIS Manufacturing isn’t just another IT vendor we’re manufacturing technology specialists who understand that every minute of downtime costs you money. Here’s what sets us apart:

Manufacturing-First Approach

– All our solutions are designed specifically for manufacturing environments

– We speak your language and understand your challenges

– Our team includes former manufacturing professionals

Proven Methodology

– Standardized implementation process refined over hundreds of projects

– Risk mitigation strategies based on real-world experience

– Measurable ROI tracking from day one

Comprehensive Support

– 24/7 monitoring and support for critical systems

– Proactive maintenance and optimization

– Regular business reviews and strategic planning

Future-Proofing Your Manufacturing IT

Emerging Technologies to Watch

The manufacturing landscape continues to evolve rapidly. To ensure your IT infrastructure doesn’t lag behind future requirements, consider these emerging trends:

Industry 4.0 Integration

– IoT sensors for comprehensive equipment monitoring

– Digital twin technology for virtual production optimization

– Augmented reality for maintenance and training

Artificial Intelligence Applications

– Computer vision for automated quality inspection

– Natural language processing for maintenance documentation

– Machine learning for predictive analytics

Edge Computing

– Local processing power for real-time decision making

– Reduced latency for time-critical applications

– Enhanced security through distributed architecture

Building Flexibility Into Your Systems

ACIS Manufacturing designs solutions with the future in mind:

Modular Architecture

– Easy integration of new technologies as they mature

– Scalable components that grow with your needs

– Standard interfaces that support vendor diversity

Continuous Learning

– Regular technology assessments and recommendations

– Training programs to keep your team current

– Strategic planning sessions to align IT with business goals

Conclusion: Don’t Let IT Lag Hold Back Your Success

In today’s competitive manufacturing environment, your IT infrastructure is your competitive advantage. When your IT lags, your assembly line does too, and so does your ability to serve customers, maintain quality, and grow your business.

The challenges we’ve discussed, legacy systems, data silos, reactive maintenance, poor visibility, cybersecurity risks, and scalability issues, aren’t just technical problems. They’re business problems that directly impact your bottom line every single day.

But here’s the good news: these problems are solvable. With the right approach, technology partner, and implementation strategy, you can transform your IT infrastructure from a liability into your greatest asset.

Your Next Steps

- Assess Your Current State: Use our downtime calculator above to quantify what IT lag is really costing your operation

- Identify Your Biggest Pain Points: Which of the six challenges we discussed resonates most with your current situation?

- Plan Your Approach: Determine whether you need quick fixes, comprehensive modernization, or something in between

- Choose the Right Partner: Find a technology provider who understands manufacturing and can deliver measurable results

Ready to Stop IT-Related Production Losses?

Don't let technology failures hold your assembly line hostage!

ACIS Manufacturing specializes in creating robust, integrated IT solutions that keep your production running smoothly. Our team of manufacturing technology experts can assess your current systems and design a roadmap to eliminate costly downtime.

📅 Book a Schedule Now

Dmitriy Teplinskiy

I have worked in the IT industry for 15+ years. During this time I have consulted clients in accounting and finance, manufacturing, automotive and boating, retail and everything in between. My background is in Networking and Cybersecurity