Picture this: It’s 3 AM, and your production line grinds to a halt because your aging ERP system just crashed. Again. Your plant manager is frantically calling the IT team, but they’re already dealing with a cybersecurity incident that started two hours ago. Meanwhile, your competitors are racing ahead with smart factories and AI-powered operations while you’re still struggling to get basic systems to talk to each other.

If this scenario sounds familiar, you’re not alone. Manufacturing companies today face an unprecedented digital transformation challenge; they need to modernize their IT infrastructure while maintaining 24/7 operations, ensuring safety, and staying competitive in an increasingly connected world.

The reality is that 74% of manufacturers report that outdated IT systems are hindering their growth, yet many feel overwhelmed by where to begin. The good news? Every challenge has a solution, and the manufacturers who tackle these IT hurdles head-on are the ones dominating their markets.

Key Takeaways

- Legacy system integration is the #1 IT challenge, but cloud-based solutions can bridge the gap without complete overhauls

- Cybersecurity threats target the manufacturing industry more than any other sector. A proactive security strategy is non-negotiable

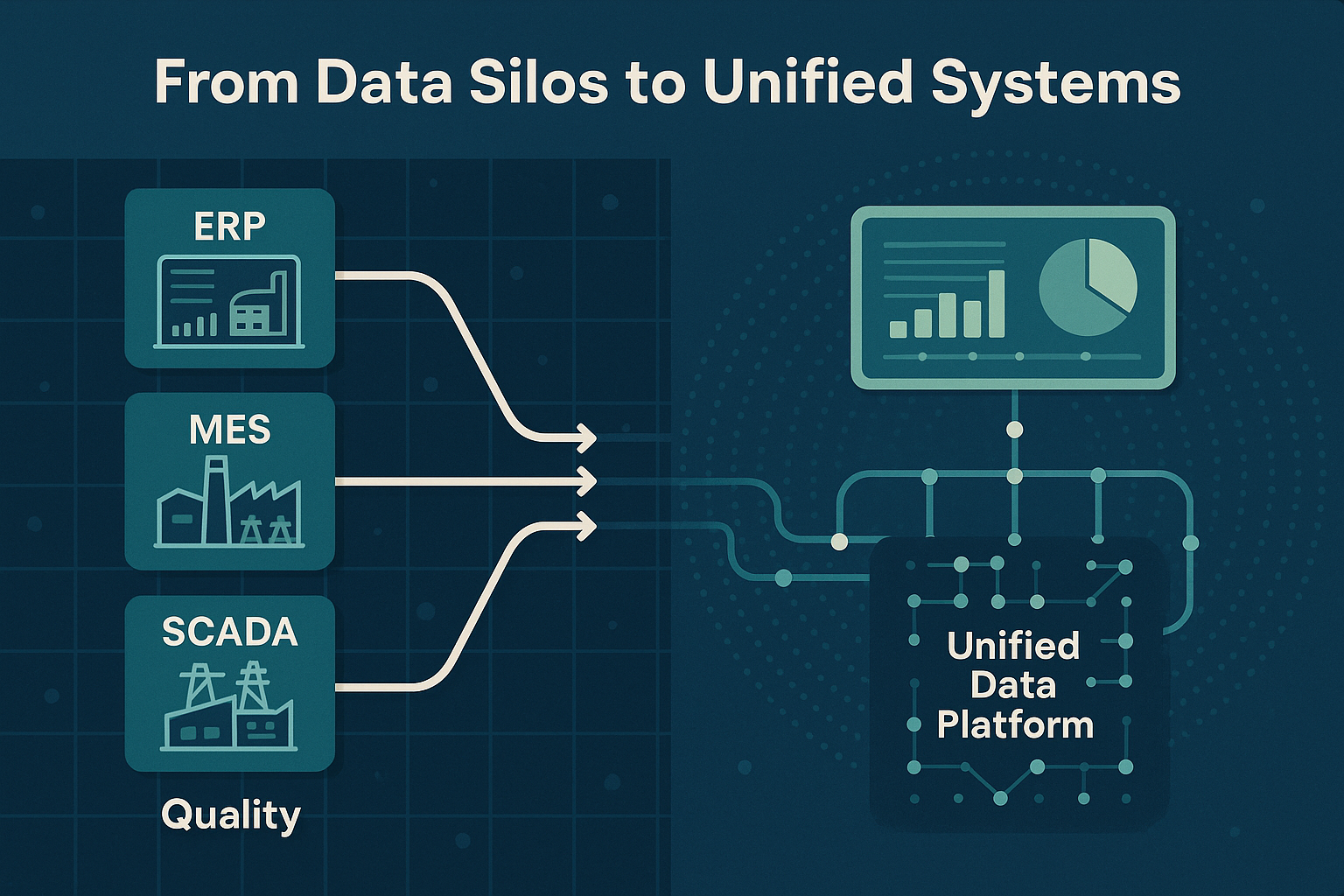

- Data silos prevent manufacturers from making informed decisions, but modern data platforms can unify information across all systems

- Skilled IT talent shortage affects 87% of manufacturers, making managed IT services and strategic partnerships crucial

- Scalability issues can be solved with a flexible, cloud-first infrastructure that grows with your business

Challenge 1: Legacy System Integration – The Manufacturing IT Nightmare

Not long ago, I visited a mid-sized automotive components plant in the Southeast. During a walkthrough with their operations team, I noticed a familiar pattern: decades-old PLCs running production lines, a 2010-era ERP handling inventory and purchasing, and a new cloud-based quality system… none of them connected.

The plant manager summed it up perfectly:

“We’re running blind. The data exists, but it lives in silos. Our machines, ERP, and quality systems all speak different languages, so we’re constantly translating, manually re-entering, and hoping nothing gets lost in the shuffle.”

This is the legacy integration problem that manufacturers everywhere are facing.

Why Legacy Integration Matters More Than Ever

Your legacy systems aren’t just outdated, they’re data islands that prevent you from getting a real-time view of your operations. When production data isn’t connected to inventory, and quality metrics don’t link to financials, you’re forced to make critical decisions based on fragmented, delayed, or incomplete information.

Here’s what it’s costing:

Manual entry errors that multiply across departments

Slow decision cycles due to a lack of centralized data

Underused equipment or resources because insights aren’t visible

Non-compliance risks when data trails are incomplete or inaccessible

The Solution: Strategic Integration Without the Rip-and-Replace Approach

You don’t have to start from scratch. Most manufacturers can modernize without replacing everything. The key is to build smart bridges between what you already use and the tools you’re adding.

Step 1: Conduct a Full System Audit

Document every system from the conveyor PLCs to the inventory module to the quality dashboard. What data does each system produce? What does it need? Mapping this flow will reveal your biggest gaps.

Step 2: Use Middleware or Integration Hubs

Modern integration platforms (middleware) act as translators, allowing old and new systems to share data without rewriting everything. These platforms can sit in the middle and connect your factory floor to your business systems.

Step 3: Start with High-Impact Data Flows

Don’t try to boil the ocean. Start by connecting your most critical points, like syncing production outputs with your ERP, or tying quality results directly into scheduling. These small wins create immediate value.

Step 4: Build with Scalability in Mind

Every integration you make should work with future systems, too. That means choosing flexible tools and API-friendly ones, so you won’t be back in the same situation five years from now.

Bottom line: Legacy systems don’t have to hold you back. With the right integration strategy, you can unlock real-time visibility, reduce errors, and make smarter decisions all without ripping out the backbone of your operation.

Challenge 2: Cybersecurity Threats – Manufacturing in the Crosshairs

It’s a harsh reality most manufacturers are waking up to: cybercriminals aren’t just targeting banks and big tech anymore, they’re coming for the shop floor.

In fact, recent industry reports confirm that manufacturing is now the most targeted sector for cyberattacks, accounting for more than a quarter of all documented incidents. Why? When a production environment goes down, the financial fallout is immediate and unforgiving: stalled output, idle workers, missed delivery windows, and potential safety risks.

One recent case I encountered involved a regional food processing facility. Their IT provider was running routine maintenance when they discovered unusual traffic patterns. After a deeper dive, they realized their network had been compromised for nearly three months. During that time, attackers had visibility into production schedules, client orders, and even control pathways to temperature-regulated storage and safety systems.

Thankfully, no damage was done, but it could have been catastrophic.

The Unique Cybersecurity Challenges in Manufacturing

Cybersecurity in manufacturing isn’t as simple as installing antivirus software and calling it a day. The challenges are deeply operational:

Operational Technology (OT) Vulnerabilities

Industrial control systems weren’t built with cybersecurity in mind. Many still use default credentials, unencrypted protocols, and outdated firmware. They were designed to last 20+ years but not to withstand modern threats.

Connected Supply Chains

Your partners, vendors, and suppliers often have digital access to your environment, and any one of them could be the open door that attackers walk through. If your supplier gets breached, so do you.

Always-On Operations

Patching a server or restarting a router in an office setting is no big deal. But on the plant floor? Shutting down a control system for a reboot can mean halting production and losing tens of thousands per hour.

Building a Manufacturing-Specific Cybersecurity Strategy

The goal isn’t to lock everything down and hope for the best. It’s to design a cybersecurity posture that respects the realities of production while keeping critical systems protected.

Layer 1: Network Segmentation

Keep your IT (business systems) and OT (factory floor) networks separated. Use firewalls and data diodes to only allow essential communication between them. This isolation limits an attacker’s ability to move laterally across your environment.

Layer 2: Real-Time Monitoring

Invest in monitoring tools designed for industrial environments. If your CNC machine suddenly starts talking to an unknown server overseas, you need alerts in seconds, not days.

Layer 3: Employee Training

Your people are often the weakest link. One click on a phishing email can bring everything down. Make cybersecurity awareness part of your safety meetings. Include real-world phishing simulations and regular refreshers.

Layer 4: Incident Response Planning

Create a response plan tailored to your environment. How do you protect employees if automation systems fail? Can you run mission-critical processes manually? Who makes the call to isolate a system?

Layer 5: Regular Security Assessments

New equipment, new software, and process changes all affect your risk. Schedule quarterly assessments to identify new vulnerabilities and patch gaps in your defenses.

Bottom line: In manufacturing, cybersecurity isn’t just about data loss; it’s about operational downtime, safety risks, and real-world financial impact. It’s time to treat it with the same priority you give to physical safety and quality control.

🚀 Ready to Fix Your IT Challenges?

Don’t wait until downtime or a cyberattack costs you thousands. Schedule your FREE Manufacturing IT Assessment today and take the first step toward a more efficient, secure, and scalable operation.

📅 Book a Schedule NowChallenge 3: Data Silos and Poor Integration – The Information Isolation Problem

Walk into any modern manufacturing facility, and you’ll see an impressive mix of systems: ERPs, MES, CMMS, QMS, SCADA, and more, each tracking a different piece of the operation. But behind the scenes, it’s a different story: data everywhere, but insights nowhere.

In one recent consultation with a medical device manufacturer, the quality and operations teams described their routine: pulling numbers from half a dozen systems, stitching them together in spreadsheets, and emailing outdated reports to leadership sometimes days after the fact.

Their exact words?

“We’re drowning in data, but starving for usable information.”

Data Silos Are Killing Manufacturing Efficiency

Data silos aren’t just annoying; they actively prevent your teams from making smart, timely decisions. When your systems don’t talk to each other, everything becomes slower, harder, and more error-prone.

The Hidden Costs of Data Silos

Reactive Instead of Predictive Operations

Without integrated data, you’re always playing catch-up. You only learn about process inefficiencies or quality issues after they’ve caused scrap, rework, or customer complaints.

Missed Optimization Opportunities

Machine vibration logs might hold the key to understanding yield issues, but you’ll never see the connection if that data isn’t tied to quality metrics or maintenance records.

Compliance and Audit Nightmares

In highly regulated industries, traceability is non-negotiable. However, when data is scattered across multiple systems, proving compliance becomes a stressful and time-consuming manual process.

Inefficient Resource Allocation

Without a comprehensive operational view, you may be over-maintaining some machines, underutilizing others, or misaligning production with demand forecasts, all of which can harm your bottom line.

Creating a Unified Data Strategy

Solving the silo problem doesn’t happen overnight. But with a phased, methodical approach, any manufacturer can regain visibility and control over their data.

Phase 1: Data Discovery and Mapping

Start by identifying every data source in your operation, not just the obvious ones. Include maintenance logs, sensor data, operator notes, and spreadsheets. Understand what data exists, where it lives, and who uses it.

Phase 2: Establish Data Standards

Unify naming conventions, measurement units, and data structures across systems. If one system uses “Part Number” and another says “SKU,” you need a common reference point for both.

Phase 3: Implement a Data Integration Platform

Modern integration platforms can bridge old and new systems, ingesting data from both real-time machine sensors and batch ERP reports and translating it into a usable format.

Phase 4: Create Unified Dashboards

Design dashboards tailored to the role: operators need machine-level visibility, supervisors need live production metrics, and executives need trend-based KPIs. When everyone sees what they need in real-time decisions improve.

Phase 5: Enable Self-Service Analytics

The goal isn’t just to centralize reports, it’s to democratize insight. Give team members the tools to ask questions and explore the data without needing to submit IT tickets or wait for custom reports.

Bottom line: Your data is one of your most valuable assets, but only if it’s connected, accessible, and actionable. Break the silos, and you unlock faster decisions, better quality, and more efficient operations.

Ready to Transform Your Manufacturing IT Infrastructure?

Don’t let IT challenges hold your manufacturing operation back any longer. AlphaCIS specializes in solving complex manufacturing IT challenges with solutions designed specifically for the unique demands of industrial environments.

Get a FREE Manufacturing IT Assessment

- Identify your biggest IT vulnerabilities

- Discover integration opportunities you might be missing

- Receive a custom roadmap for your digital transformation

- Learn how other manufacturers solved similar challenges

🚀 Ready to Fix Your IT Challenges?

Don’t wait until downtime or a cyberattack costs you thousands. Schedule your FREE Manufacturing IT Assessment today and take the first step toward a more efficient, secure, and scalable operation.

📅 Book a Schedule NowChallenge 4: Lack of Skilled IT Personnel – The Talent Crisis in Manufacturing

Here’s a reality check that hits across the industry: 87% of manufacturing companies report difficulty finding qualified IT personnel. And the problem isn’t just about filling seats with people who understand technology; it’s about finding professionals who also understand manufacturing environments, industrial protocols, and the 24/7 reality of production.

In one case, a chemical processing facility shared the frustration clearly:

“We need someone who can troubleshoot a network outage at 2 AM, understands SCADA and PLCs, knows cybersecurity, and can explain it all to operators who’ve been running machines for 20 years. That’s not exactly a common skill set.”

This combination of IT and OT expertise, paired with round-the-clock availability, is one of the toughest challenges manufacturers face today.

Why Manufacturing IT Is Different from Traditional IT

Industrial Environment Expertise

In manufacturing, downtime isn’t a mild inconvenience; it’s potentially tens of thousands of dollars lost per hour. IT teams need to know which systems are safety-critical and which can wait for a planned maintenance window.

Operational Technology (OT) Knowledge

Beyond servers and business apps, IT staff must understand OT: PLCs, HMIs, SCADA, and protocols like Modbus or Ethernet/IP. This is a completely different world from traditional IT.

24/7 Availability Requirements

Production doesn’t stop on weekends or holidays. IT coverage must align with nonstop operations.

Cross-Functional Communication Skills

IT needs to collaborate with production operators, maintenance technicians, engineers, and executives, each with different levels of technical expertise and very different priorities.

Strategic Solutions for the IT Talent Gap

Solution 1: Hybrid Internal/External Model

Keep a lean in-house team for daily support, and supplement with specialized external partners for complex projects and advanced technologies.

Solution 2: Invest in Training and Development

Upskill your existing IT staff with manufacturing-specific training. Many talented IT professionals can adapt to OT systems when given the opportunity.

Solution 3: Managed IT Services for Manufacturing

Partner with providers who specialize in manufacturing IT. They bring proven expertise and can offer 24/7 support without the overhead of a large internal staff.

Solution 4: Automation and Self-Healing Systems

Deploy monitoring tools and automation that resolve common issues automatically. This reduces the reliance on human intervention for routine problems.

Solution 5: Cross-Training Programs

Train production and maintenance teams in basic IT troubleshooting. They don’t need to be experts, just skilled enough to handle minor issues and provide better detail when escalating.

Building Your IT Dream Team

- Start with Core Competencies: Identify must-have skills like networking, cybersecurity, and system integration, and secure those first.

- Create Clear Career Paths: Offer advancement opportunities so IT professionals see manufacturing as a career, not a temporary stop.

- Develop Strong Vendor Relationships: Lean on trusted vendors and integrators for specialized system support.

- Implement Knowledge Management: Document systems, configurations, and troubleshooting steps to preserve knowledge and ease the onboarding of new talent.

Bottom line: The manufacturing IT talent gap isn’t going away anytime soon. But with the right mix of training, external support, and smart processes, you can build a resilient IT capability that keeps your operations secure, connected, and running around the clock.

Challenge 5: Scalability and Future-Proofing – Building for Tomorrow’s Manufacturing

The final challenge might be the most critical: How do you build IT systems that can grow and adapt with your business? I’ve seen too many manufacturers implement solutions that work great today but become bottlenecks within two years.

Consider this scenario: A packaging company I worked with implemented a new MES system designed for their current production volume of 10,000 units per day. Eighteen months later, they landed a major contract that tripled their volume, but their MES couldn’t handle the load. They faced a choice between losing the contract and scrambling to implement a new system while trying to fulfill increased demand.

The Scalability Trap in Manufacturing IT

Capacity Planning Challenges

Manufacturing growth often comes in large jumps rather than gradual increases. A new customer contract might double your production overnight, but IT systems that work fine at current volumes might crash under increased load.

Technology Evolution Speed

The pace of technological change in manufacturing is accelerating. IoT sensors, artificial intelligence, machine learning, and edge computing are moving from “nice to have” to “competitive necessity” faster than ever.

Integration Complexity

As you add new systems and capabilities, the complexity of integrating everything grows exponentially. What starts as a simple point-to-point connection becomes a web of interdependencies that’s difficult to manage and modify.

Budget Constraints vs. Future Needs

You need to balance current budget realities with future requirements. Over-engineering for scenarios that might never happen wastes money, but under-engineering creates expensive problems later.

Building Scalable Manufacturing IT Architecture

Principle 1: Cloud-First Thinking

Modern cloud platforms offer virtually unlimited scalability. Instead of buying servers for peak capacity that sit idle most of the time, cloud solutions let you scale up during busy periods and scale down during slower times.

Principle 2: API-Driven Architecture

Choose systems that offer robust APIs (Application Programming Interfaces). APIs make it easier to integrate new systems and replace old ones without disrupting your entire infrastructure.

Principle 3: Modular System Design

Instead of monolithic systems that do everything, choose modular solutions where you can add capabilities as needed. This approach lets you start small and expand without replacing your entire system.

Principle 4: Data-Centric Approach

Design your architecture around your data, not your current applications. Applications will change over time, but your data is your most valuable asset. Make sure it’s stored in formats and systems that can be accessed by future technologies.

Principle 5: Performance Monitoring and Capacity Planning

Implement monitoring that tracks not just current performance but also trends over time. This helps you predict when you’ll need additional capacity and plan upgrades before they become emergencies.

Future-Proofing Strategies

Stay Informed About Emerging Technologies

You don’t need to implement every new technology immediately, but you should understand how emerging trends might affect your industry. Technologies like digital twins, predictive analytics, and autonomous systems are becoming mainstream in manufacturing.

Build Partnerships with Forward-Thinking Vendors

Choose technology partners who are investing in research and development. Vendors who are actively developing new capabilities are more likely to provide upgrade paths that protect your investment.

Implement Flexible Licensing Models

Look for software licensing that can scale with your usage rather than requiring large upfront commitments. This approach reduces risk and makes it easier to adjust as your needs change.

Create a Technology Roadmap

Develop a 3-5 year plan for your IT infrastructure that aligns with your business growth plans. This roadmap should be reviewed and updated annually as business conditions and technology options evolve.

Putting It All Together: Your Manufacturing IT Transformation Roadmap

Now that we’ve explored the top 5 IT challenges manufacturers face, let’s talk about how to tackle them systematically. The key is to approach these challenges strategically rather than reactively.

Phase 1: Assessment and Planning (Months 1-2)

Comprehensive IT Audit

Document your current systems, identify integration points, and assess security vulnerabilities. This baseline assessment is crucial for making informed decisions about where to invest your time and resources.

Risk Assessment and Prioritization

Not all challenges need to be solved immediately. Prioritize based on business impact, security risk, and available resources. A cybersecurity vulnerability that could shut down production takes priority over a data integration project that would improve efficiency.

Stakeholder Alignment

Get buy-in from all stakeholders: production managers, quality teams, maintenance staff, and executives. Each group will have different priorities and concerns that need to be addressed in your IT strategy.

Phase 2: Quick Wins and Foundation Building (Months 3-6)

Implement Basic Security Measures

Start with fundamental cybersecurity improvements like network segmentation, employee training, and basic monitoring. These provide immediate risk reduction while you plan more comprehensive solutions.

Address Critical Integration Points

Identify the most important data flows between systems and implement basic integration solutions. Even simple automated data transfers can eliminate manual processes and reduce errors.

Establish Monitoring and Alerting

Implement monitoring systems that give you visibility into your IT infrastructure performance. You can’t manage what you can’t measure.

Phase 3: Strategic Implementation (Months 6-18)

Deploy a Comprehensive Integration Platform

Implement a robust integration platform that can handle current needs and scale for future requirements. This becomes the foundation for all future system additions and upgrades.

Enhance Cybersecurity Posture

Move beyond basic security to implement advanced threat detection, incident response procedures, and regular security assessments.

Build Data Analytics Capabilities

Create unified data platforms and analytics capabilities that turn your integrated data into actionable insights.

Phase 4: Optimization and Innovation (Months 18+)

Continuous Improvement Process

Establish regular review cycles to assess system performance, identify new opportunities, and plan future enhancements.

Emerging Technology Evaluation

Begin evaluating and piloting emerging technologies like IoT sensors, predictive analytics, and artificial intelligence that can provide competitive advantages.

Scale and Expand

Use the foundation you’ve built to rapidly deploy new capabilities as business needs evolve.

Real-World Success Stories: Manufacturers Who Got It Right

Let me share a few examples of manufacturers who successfully tackled these IT challenges:

Case Study 1: Regional Food Processor

This company was struggling with food safety compliance because its quality data was scattered across multiple systems. They implemented a unified data platform that automatically compiled compliance reports and provided real-time alerts for quality issues. Result: 90% reduction in compliance preparation time and zero food safety incidents in the following year.

Case Study 2: Automotive Parts Manufacturer

Facing cybersecurity concerns and aging systems, this manufacturer implemented network segmentation and a comprehensive monitoring system. When a cyberattack targeted their industry six months later, their systems detected and blocked the intrusion automatically. Their competitors weren’t so fortunate.

Case Study 3: Chemical Processing Plant

This facility solved its IT talent shortage by partnering with a managed services provider while training its existing maintenance staff on basic IT troubleshooting. They reduced system downtime by 60% while actually decreasing their IT-related costs.

The Cost of Inaction: What Happens If You Don’t Address These Challenges

I’ve seen the consequences when manufacturers postpone addressing these IT challenges:

- Production downtime that costs tens of thousands of dollars per hour

- Cybersecurity breaches that result in weeks of recovery time and damaged customer relationships

- Missed opportunities for efficiency improvements that competitors capitalize on

- Compliance failures that result in fines, recalls, and regulatory scrutiny

- Inability to scale when growth opportunities arise

The manufacturers who are thriving today are the ones who viewed IT challenges as competitive opportunities rather than necessary evils.

Your Next Steps: From Challenge to Competitive Advantage

Here’s your action plan for the next 30 days:

Week 1: Assessment

Document your current IT systems and identify the biggest pain points

Survey your team to understand which challenges are causing the most frustration

Research potential solutions and vendors for your priority challenges

Week 2: Planning

Create a preliminary roadmap for addressing your top 3 IT challenges

Estimate the costs and benefits of potential solutions

Identify internal resources and external partners you’ll need

Week 3: Stakeholder Engagement

Present your findings to key stakeholders and get their input

Refine your plan based on their feedback and priorities

Secure preliminary budget approval for your priority initiatives

Week 4: Implementation Preparation

Begin vendor evaluations for your priority solutions

Start planning for any necessary infrastructure changes

Develop a communication plan for rolling out changes to your team

Remember, you don’t have to solve everything at once. Start with the challenge that’s causing the most pain or risk for your organization, implement a solution, and build momentum for tackling the next challenge.

Conclusion

The top 5 IT challenges manufacturers face are legacy system integration, cybersecurity threats, data silos, skilled personnel shortages, and scalability issues might seem overwhelming, but they’re absolutely solvable. The manufacturers who are winning in today’s competitive landscape are the ones who view these challenges as opportunities to build competitive advantages.

Every day you postpone addressing these challenges is another day your competitors might be pulling ahead. But every step you take toward solving them is progress toward a more efficient, secure, and profitable operation.

The key is to start somewhere and build momentum. Whether you begin with a basic cybersecurity assessment, a simple system integration project, or partnering with a managed services provider, the important thing is to take action.

Your manufacturing operation deserves IT systems that enhance rather than hinder your success. The solutions exist, the technology is proven, and the return on investment is compelling. The only question is: When will you start?

Final Call to Action: Transform Your Manufacturing IT Today

Don’t let another day pass with IT systems that hold your manufacturing operation back. The challenges we’ve discussed affect every aspect of your business – from production efficiency to cybersecurity to competitive positioning.

AlphaCIS has helped dozens of manufacturers just like yours solve these exact challenges. We understand the unique requirements of manufacturing environments and have proven solutions that work in the real world.

🚀 Ready to Fix Your IT Challenges?

Don’t wait until downtime or a cyberattack costs you thousands. Schedule your FREE Manufacturing IT Assessment today and take the first step toward a more efficient, secure, and scalable operation.

📅 Book a Schedule NowTake the first step today:

Schedule a free consultation to discuss your specific challenges

Get a customized assessment of your current IT infrastructure

Receive a detailed roadmap for transforming your manufacturing IT systems

Learn how other manufacturers in your industry solved similar problems

Contact AlphaCIS today and discover how the right IT strategy can transform your manufacturing operation from a cost center into a competitive advantage.

Your future success starts with the decisions you make today. Decide to move forward.

Manufacturing IT Risk Assessment

Evaluate your manufacturing facility's IT challenges and get personalized recommendations

Recommended Next Steps:

Dmitriy Teplinskiy

I have worked in the IT industry for 15+ years. During this time I have consulted clients in accounting and finance, manufacturing, automotive and boating, retail and everything in between. My background is in Networking and Cybersecurity