Picture this: It’s 3 AM, and your production line just went down. Your current MSP’s response? “We’ll have someone look at it during business hours.” Meanwhile, every minute of downtime costs you thousands of dollars and potentially damages relationships with key customers. This scenario plays out in manufacturing facilities across the country every day, and it’s exactly why traditional managed service providers (MSPs) often fall short in the manufacturing sector.

The truth is, manufacturing isn’t just another industry that needs IT support. It’s a complex ecosystem where technology directly impacts production output, quality control, and ultimately, your bottom line. When your tech partner doesn’t understand the unique pressures and requirements of manufacturing, you’re not just getting subpar IT support; you’re risking your entire operation.

Key Takeaways

Ready to Take IT Off Your Plate?

Stop worrying about downtime, security risks, or endless IT frustrations. AlphaCIS is the trusted IT partner for small and mid-sized businesses in Metro Atlanta, keeping systems secure, connected, and running the way they should every day.

Whether it’s preventing costly outages, protecting your data, or giving your team unlimited support, we make sure technology helps your business grow instead of holding it back.

📅 Book Your Free Consultation- Manufacturing requires specialized IT expertise that goes beyond basic network maintenance and email support

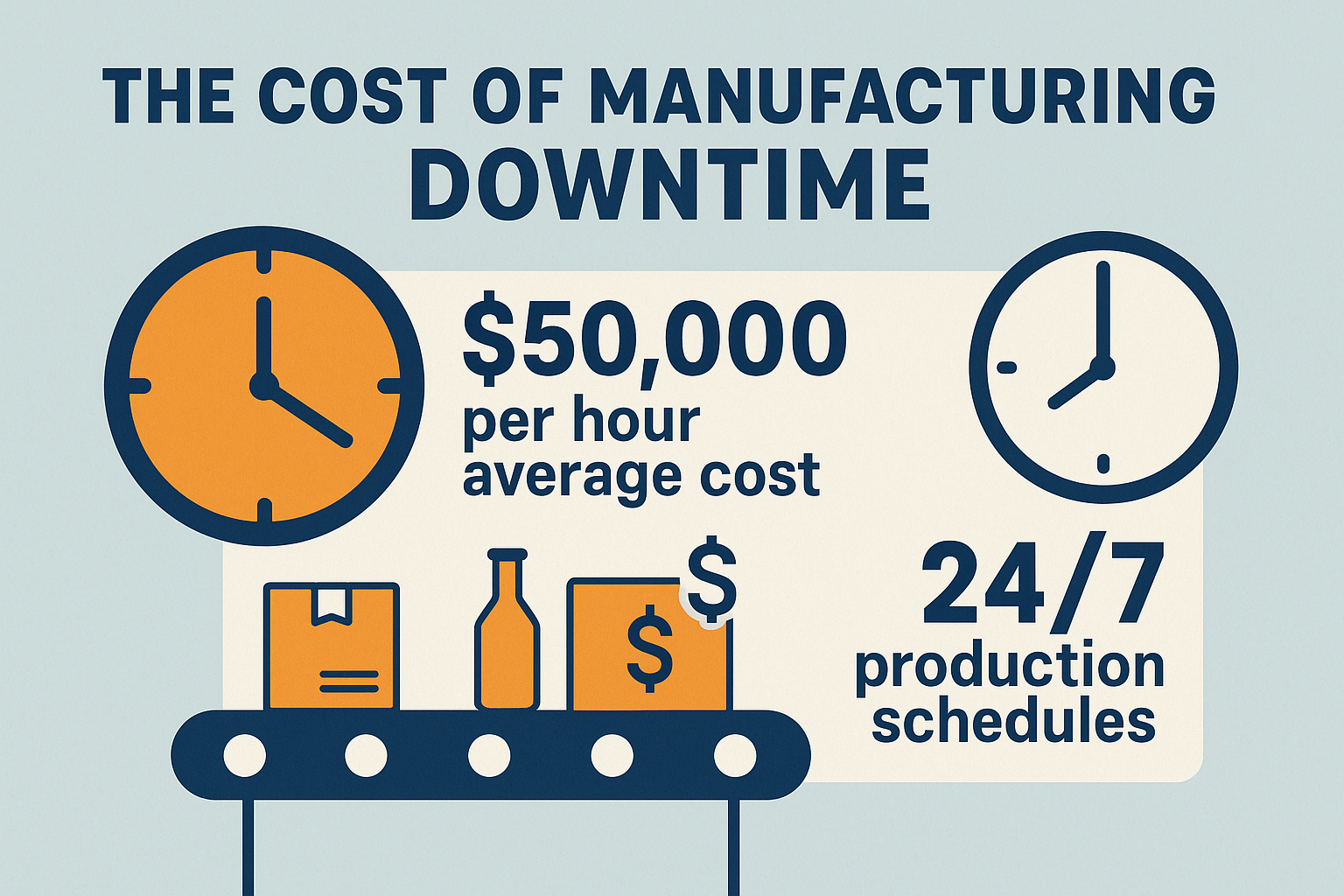

- Production downtime costs manufacturers an average of $50,000 per hour, making rapid response times critical

- Traditional MSPs lack industry-specific knowledge about manufacturing systems, compliance requirements, and operational workflows

- A true tech partner understands your production environment and can proactively prevent issues before they impact your operations

- The right partnership combines technical expertise with manufacturing industry experience to drive both efficiency and growth

The Critical Gap: Why Generic IT Support Fails Manufacturing

Understanding the Manufacturing Technology Landscape

Manufacturing in 2025 isn’t what it was even five years ago. Today’s facilities are powered by sophisticated networks of interconnected systems: Industrial IoT sensors, SCADA systems, MES (Manufacturing Execution Systems), ERP platforms, and automated quality control systems. Each of these components plays a vital role in keeping production running smoothly.

I remember working with a mid-sized automotive parts manufacturer who had been struggling with their previous MSP for months. Every time their CNC machines went offline, the MSP would treat it like a standard network issue. They’d run basic diagnostics, restart routers, and call it fixed, only to have the same problem resurface days later.

The real issue? Their industrial network required specialized protocols and security measures that their generic MSP simply didn’t understand. What should have been a quick fix turned into weeks of production delays and frustrated customers.

The Hidden Costs of Mismatched IT Support

When your MSP doesn’t understand manufacturing, the costs add up quickly:

Direct Production Losses:

– Average manufacturing downtime costs: $50,000 per hour

– Lost productivity during system slowdowns

– Overtime costs to make up for delays

– Rush shipping fees to meet customer deadlines

Indirect Impact:

– Damaged customer relationships

– Missed delivery commitments

– Increased stress on production teams

– Potential safety risks from malfunctioning systems

Compliance Risks:

– Failed quality audits due to system issues

– Regulatory violations in controlled environments

– Data integrity problems affecting traceability

Challenge 1: Response Time vs. Production Reality

The Problem: Business Hours Don’t Match Production Schedules

Most traditional MSPs operate on a 9-to-5 business model. But manufacturing? Manufacturing runs 24/7, 365 days a year. When your third shift encounters a critical system failure at 2 AM, you can’t wait until Monday morning for a response.

Why It Matters: Every Minute Counts

In manufacturing, time literally equals money. A single hour of downtime can result in:

– Thousands of units of lost production

– Spoiled materials that can’t be processed

– Cascade effects that impact multiple production lines

– Customer penalties for missed deliveries

The Solution: 24/7 Manufacturing-Focused Support

A true manufacturing tech partner understands that your operations never stop. They provide:

Round-the-clock monitoring of critical systems

Immediate response protocols for production-impacting issues

On-site emergency support when remote fixes aren’t enough

Proactive maintenance scheduled during planned downtime

Challenge 2: Security Needs That Go Beyond Standard IT

The Problem: Manufacturing Systems Require Specialized Security

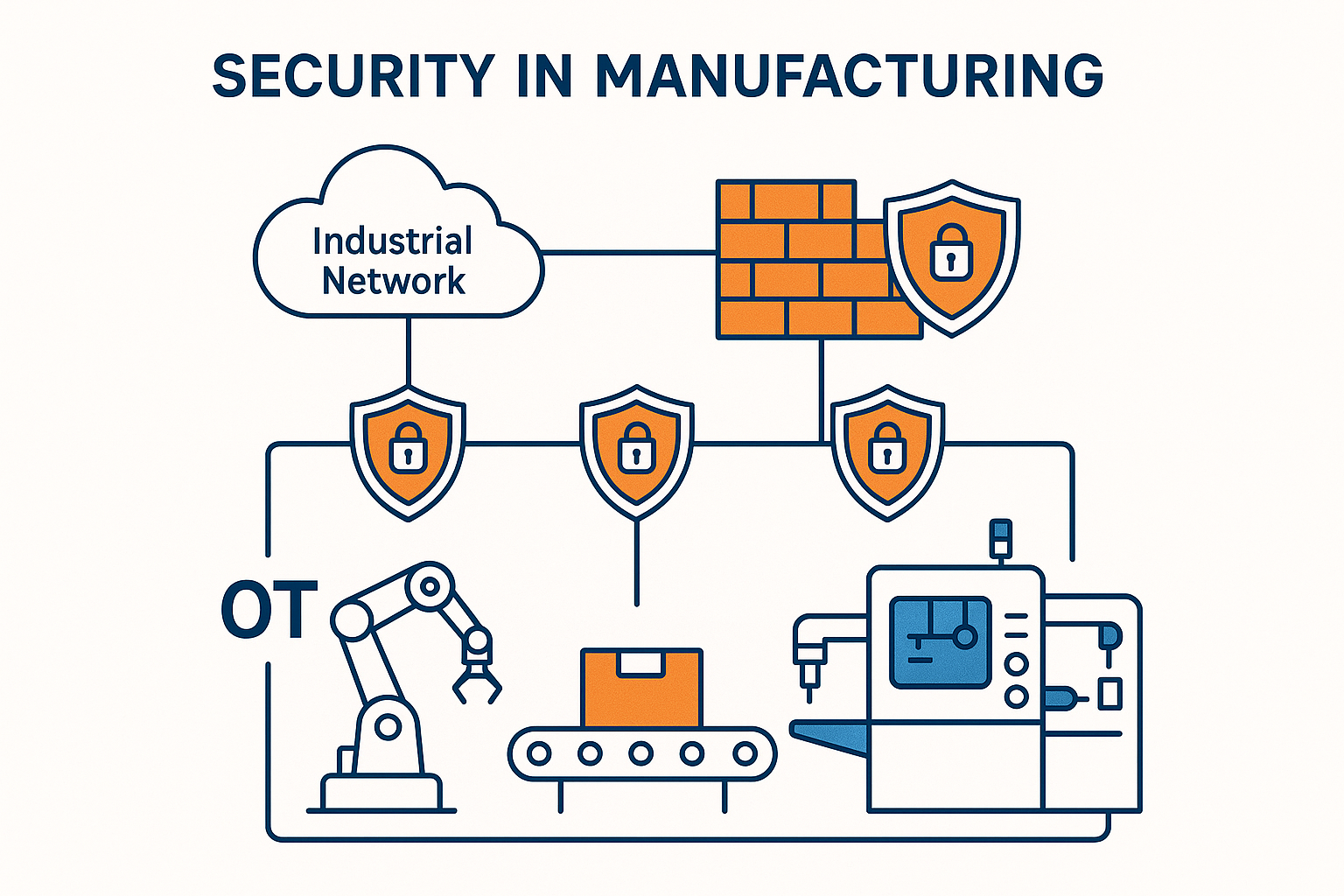

Your OT (Operational Technology) networks aren’t just another IT system. They control physical processes, manage safety systems, and often can’t be patched or updated using standard IT practices. A generic MSP might implement security measures that actually disrupt production or leave critical vulnerabilities unaddressed.

Why It Matters: The Stakes Are Higher

Manufacturing cybersecurity isn’t just about protecting data; it’s about protecting:

– Physical safety of workers

– Production continuity and supply chain integrity

– Intellectual property and trade secrets

– Regulatory compliance in controlled industries

The Solution: OT-Aware Security Strategies

Manufacturing-focused tech partners implement security measures that protect without disrupting:

Network segmentation that isolates critical systems

Industrial-grade firewalls designed for OT environments

Specialized monitoring for unusual operational patterns

Compliance-ready documentation for audits and certifications

Challenge 3: Integration Complexity in Modern Manufacturing

The Problem: Legacy Systems Meet Modern Technology

Manufacturing facilities often operate with a mix of cutting-edge technology and legacy systems that have been running reliably for decades. A generic MSP might push for complete system overhauls that aren’t practical or necessary, while missing opportunities for strategic upgrades that could dramatically improve efficiency.

Why It Matters: Balance Innovation with Reliability

The goal isn’t to replace everything, it’s to create a cohesive technology ecosystem that:

– Maximizes the value of existing investments

– Enables data flow between systems

– Supports gradual, strategic modernization

– Maintains production stability during transitions

The Solution: Strategic Technology Integration

Manufacturing tech partners excel at:

Bridging old and new systems with appropriate interfaces

Phased modernization approaches that minimize disruption

Custom integration solutions for unique manufacturing processes

Future-proofing strategies that support long-term growth

Challenge 4: Compliance and Documentation Requirements

The Problem: Manufacturing Regulations Are Complex and Evolving

Depending on your industry, you might need to comply with FDA regulations, ISO standards, OSHA requirements, or environmental regulations. Each of these has specific IT and documentation requirements that generic MSPs often overlook or handle inadequately.

I worked with a food processing company that nearly failed an FDA audit because their previous MSP hadn’t properly configured their traceability systems. The MSP had treated it like a basic database issue, not understanding the critical regulatory implications of data integrity in food manufacturing.

Why It Matters: Compliance Failures Can Shut You Down

Non-compliance isn’t just about fines; it can mean:

– Production shutdowns until issues are resolved

– Product recalls that damage your brand

– Lost certifications that block market access

– Legal liability for safety or quality issues

The Solution: Compliance-First IT Management

Manufacturing tech partners understand regulatory requirements and ensure:

Automated compliance reporting and documentation

Audit-ready system configurations and access logs

Validated system changes with proper approval workflows

Regular compliance assessments and remediation plans

Challenge 5: Scalability for Manufacturing Growth

The Problem: Generic Solutions Don’t Scale with Production Needs

As your manufacturing operation grows, your technology needs become more complex. You might add new production lines, expand to multiple facilities, or integrate with new suppliers and customers. A traditional MSP often approaches this with standard business IT solutions that don’t address manufacturing-specific scalability challenges.

Why It Matters: Growth Shouldn’t Mean Growing Pains

Effective scaling in manufacturing requires:

– Consistent performance across multiple facilities

– Standardized processes that maintain quality

– Integrated data flows for enterprise-wide visibility

– Flexible architectures that adapt to changing needs

The Solution: Manufacturing-Aware Growth Planning

True tech partners help you scale by:

Designing scalable architectures from the start

Standardizing configurations across facilities

Planning capacity for peak production periods

Implementing enterprise integration strategies

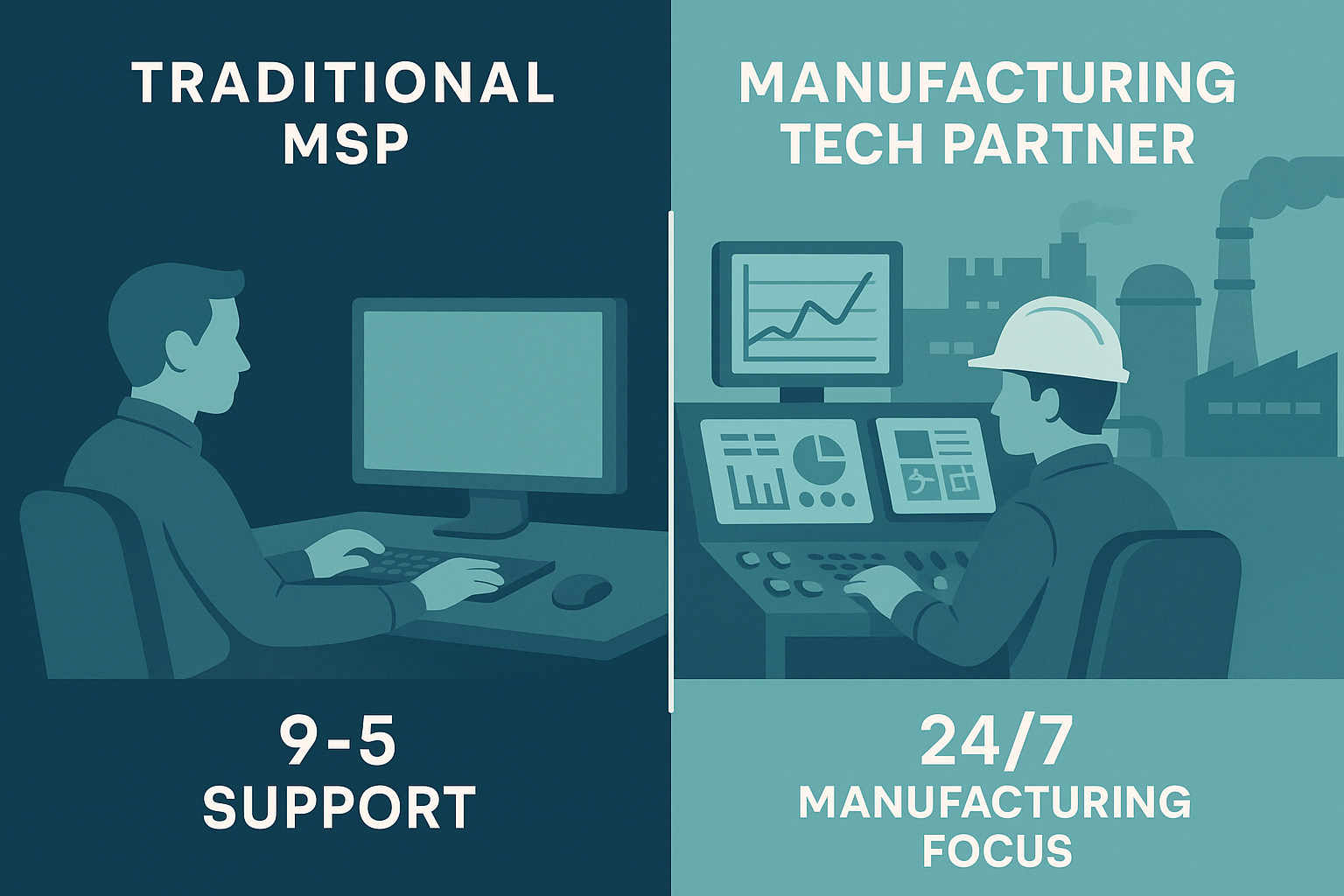

Traditional MSP vs Manufacturing Tech Partner

Compare key differences in approach, expertise, and value delivery

🕐 Support & Response

🔒 Security Approach

🎯 Industry Expertise

⚡ Downtime Response

📋 Compliance Management

📈 Growth Planning

Ready to Take IT Off Your Plate?

Stop worrying about downtime, security risks, or endless IT frustrations. AlphaCIS is the trusted IT partner for small and mid-sized businesses in Metro Atlanta, keeping systems secure, connected, and running the way they should every day.

Whether it’s preventing costly outages, protecting your data, or giving your team unlimited support, we make sure technology helps your business grow instead of holding it back.

📅 Book Your Free ConsultationWhat Makes a True Manufacturing Tech Partner Different

Deep Industry Knowledge

A manufacturing-focused tech partner brings years of industry experience to every interaction. They understand:

– Production flow dynamics and how technology impacts efficiency

– Quality control systems and their integration requirements

– Supply chain technology and vendor management systems

– Regulatory landscapes across different manufacturing sectors

– Safety protocols and how technology supports worker protection

Proactive Problem Prevention

Instead of just responding to issues, manufacturing tech partners focus on preventing problems before they impact production:

Predictive monitoring that identifies potential failures

Scheduled maintenance during planned downtime

Performance optimization to prevent slowdowns

Capacity planning to avoid bottlenecks

Strategic Technology Roadmapping

True partners don’t just maintain your current systems; they help you plan for the future:

– Technology assessments that identify improvement opportunities

– ROI analysis for potential upgrades and investments

– Integration planning for new equipment and systems

– Digital transformation strategies that align with business goals

The ROI of Choosing the Right Tech Partner

Quantifiable Benefits

Manufacturers who switch from generic MSPs to specialized tech partners typically see:

Reduced Downtime:

– 40-60% reduction in unplanned outages

– Faster resolution times for critical issues

– Better prevention of cascade failures

Improved Efficiency:

– 15-25% improvement in overall equipment effectiveness (OEE)

– Better integration between systems

– Streamlined workflows and processes

Cost Savings:

– Lower total cost of ownership for IT systems

– Reduced emergency repair costs

– Better budget predictability

Long-Term Value Creation

Beyond immediate improvements, the right tech partner helps create lasting competitive advantages:

Innovation enablement through strategic technology adoption

Scalability that supports business growth

Risk mitigation through robust security and compliance

Competitive differentiation through technology-driven capabilities

Red Flags: Signs Your Current MSP Isn’t Right for Manufacturing

Warning Signs to Watch For

If you’re experiencing any of these issues, it might be time to consider a manufacturing-focused alternative:

Slow response times during production hours

Lack of understanding of your manufacturing processes

Generic solutions that don’t fit your specific needs

Compliance gaps or audit findings related to IT systems

Resistance to manufacturing-specific requirements

Limited availability during your critical operating hours

High turnover in their technical staff assigned to your account

The Hidden Costs of Staying with the Wrong Provider

Sticking with an inadequate MSP costs more than you might realize:

– Lost production time due to longer resolution times

– Missed opportunities for efficiency improvements

– Compliance risks that could result in penalties

– Security vulnerabilities that put your operations at risk

– Frustrated staff dealing with recurring technical issues

Making the Transition: What to Expect

Evaluation Phase

A reputable manufacturing tech partner will start with a comprehensive assessment of your current environment:

– Technology audit of all systems and infrastructure

– Process analysis to understand workflow dependencies

– Risk assessment for security and compliance gaps

– Performance benchmarking to establish baseline metrics

Transition Planning

The best partners make transitions smooth and minimally disruptive:

Phased approach that maintains operational continuity

Detailed timeline with clear milestones

Staff training on new processes and procedures

Fallback plans to minimize risk during transition

Ongoing Partnership

Once established, your manufacturing tech partner becomes an extension of your team:

– Regular strategic reviews to assess performance and plan improvements

– Proactive recommendations for technology upgrades and optimizations

– Industry insights about emerging technologies and best practices

– Collaborative planning for future growth and expansion

Industry-Specific Considerations

Automotive Manufacturing

The automotive industry has unique requirements that generic MSPs often struggle with:

– Just-in-time production demands ultra-reliable systems

– Quality traceability requires robust data management

– Supplier integration needs seamless communication systems

– Regulatory compliance varies by market and component type

Food and Beverage

Food manufacturing presents specific challenges:

– HACCP compliance requires detailed monitoring and documentation

– Temperature control systems need specialized monitoring

– Batch tracking demands precise data integrity

– FDA regulations require validated system configurations

Pharmaceutical

Pharmaceutical manufacturing is among the most regulated:

– GMP compliance requires extensive documentation and validation

– Batch records must be maintained with complete integrity

– Environmental monitoring needs continuous data collection

– Audit trails must be comprehensive and tamper-proof

Electronics Manufacturing

Electronics manufacturing faces unique technology challenges:

– ESD protection requires specialized environmental controls

– Component traceability demands detailed supply chain visibility

– Quality testing integration with production systems

– Rapid product changes require flexible system configurations

Building Your Technology Strategy for Manufacturing Success

Assessing Your Current State

Before making any changes, it’s important to honestly evaluate where you stand:

Technology Infrastructure:

– Are your systems reliable and properly maintained?

– Do you have adequate redundancy for critical processes?

– Are your networks properly segmented for security?

Support Quality:

– How quickly are issues resolved?

– Do you get proactive recommendations for improvements?

– Is support available when you need it most?

Strategic Alignment:

– Does your technology support your business goals?

– Are you prepared for future growth and changes?

– Do you have a clear technology roadmap?

Defining Your Requirements

Every manufacturing operation is unique. Your ideal tech partner should understand and address your specific needs:

Production schedules and critical operating hours

Compliance requirements for your industry and markets

Integration needs with existing equipment and systems

Growth plans and scalability requirements

Budget constraints and ROI expectations

Selecting the Right Partner

When evaluating potential manufacturing tech partners, consider:

Experience and Expertise:

– Do they have proven experience in your industry?

– Can they provide references from similar manufacturers?

– Do their technical staff understand manufacturing processes?

Service Capabilities:

– Do they offer 24/7 support during your operating hours?

– Can they provide on-site support when needed?

– Do they have experience with your specific technologies?

Strategic Vision:

– Do they understand your business goals?

– Can they help you plan for future technology needs?

– Do they stay current with industry trends and innovations?

The Future of Manufacturing Technology

Emerging Trends to Watch

Manufacturing technology continues to evolve rapidly. The right tech partner helps you navigate these changes:

Industrial IoT (IIoT):

– Sensor networks for real-time monitoring

– Predictive maintenance capabilities

– Data-driven decision making

Artificial Intelligence:

– Quality control automation

– Predictive analytics for optimization

– Intelligent scheduling and planning

Edge Computing:

– Reduced latency for critical processes

– Improved data security and privacy

– Better integration with legacy systems

Digital Twins:

– Virtual modeling of production processes

– Simulation and optimization capabilities

– Improved troubleshooting and planning

Preparing for Tomorrow

A manufacturing-focused tech partner helps you prepare for the future by:

Staying informed about emerging technologies

Evaluating opportunities for competitive advantage

Planning implementations that align with business goals

Managing risks associated with new technology adoption

Taking Action: Your Next Steps

Immediate Actions You Can Take

- Assess your current IT support using the criteria discussed in this article

- Document recurring issues and their impact on production

- Calculate the true cost of downtime and inefficiencies

- Research manufacturing-focused tech partners in your area

- Schedule consultations with potential partners

Questions to Ask Potential Partners

When evaluating manufacturing tech partners, ask these key questions:

“How many manufacturing clients do you currently support?”

“What’s your average response time for production-critical issues?”

“Can you provide references from companies in our industry?”

“How do you handle compliance and regulatory requirements?”

“What’s your approach to preventive maintenance and monitoring?”

“How do you stay current with manufacturing technology trends?”

Building Your Business Case

When presenting the need for a manufacturing-focused tech partner to leadership, focus on:

Financial Impact:

– Cost of current downtime and inefficiencies

– Potential savings from improved reliability

– ROI projections for better technology support

Risk Mitigation:

– Compliance and regulatory risks

– Security vulnerabilities

– Business continuity concerns

Growth Enablement:

– Technology’s role in competitive advantage

– Scalability for future expansion

– Innovation opportunities

Conclusion

The manufacturing landscape in 2025 demands more than generic IT support. Your production environment is too complex, too critical, and too valuable to trust to a provider who treats it like just another office network. The difference between a traditional MSP and a true manufacturing tech partner isn’t just about technical expertise; it’s about understanding that in manufacturing, technology isn’t just a support function, it’s the backbone of your entire operation.

Every minute of downtime, every compliance gap, every security vulnerability, and every missed optimization opportunity represents real money and real competitive disadvantage. You can’t afford to settle for “good enough” when it comes to your technology infrastructure.

The manufacturers who thrive in today’s competitive environment are those who recognize that technology is a strategic asset, not just a necessary expense. They partner with providers who understand their industry, speak their language, and share their commitment to operational excellence.

The question isn’t whether you can afford to switch to a manufacturing-focused tech partner; it’s whether you can afford not to. Your competition is already looking for every possible advantage. Don’t let inadequate IT support be the thing that holds you back.

Ready to Take IT Off Your Plate?

Stop worrying about downtime, security risks, or endless IT frustrations. AlphaCIS is the trusted IT partner for small and mid-sized businesses in Metro Atlanta, keeping systems secure, connected, and running the way they should every day.

Whether it’s preventing costly outages, protecting your data, or giving your team unlimited support, we make sure technology helps your business grow instead of holding it back.

📅 Book Your Free Consultation

Dmitriy Teplinskiy

I have worked in the IT industry for 15+ years. During this time I have consulted clients in accounting and finance, manufacturing, automotive and boating, retail and everything in between. My background is in Networking and Cybersecurity