Picture this: You walk into a state-of-the-art manufacturing facility. Gleaming machines hum with precision, robotic arms dance in perfect choreography, and production lines move with clockwork efficiency. Yet somehow, orders are delayed, inventory is mismanaged, and productivity targets remain frustratingly out of reach.

Sound familiar? You’re not alone.

If this scenario sounds familiar, you’re not alone. Manufacturing companies today face an unprecedented digital transformation challenge; they need to modernize their IT infrastructure while maintaining 24/7 operations, ensuring safety, and staying competitive in an increasingly connected world.

In how many years working with manufacturers across industries, I’ve discovered a surprising truth: every manufacturer has a bottleneck, and for most, it’s not the machine—it’s the IT infrastructure that’s supposed to support those million-dollar machines. While companies invest heavily in cutting-edge equipment, they often overlook the digital backbone that makes modern manufacturing possible.

Key Takeaways

- Legacy IT systems are the hidden bottleneck slowing down 78% of manufacturers, not equipment limitations

- Poor data integration between systems costs manufacturers an average of $50 million annually in lost productivity

- Outdated cybersecurity exposes manufacturers to risks that could shut down operations for weeks

- Manual processes disguised as “digital solutions” create inefficiencies that compound across the entire operation

- Strategic IT modernization can unlock 25-40% productivity gains without buying a single new machine

The Hidden Truth About Manufacturing Bottlenecks

Why Everyone Looks at Machines First

When production slows down, it’s natural to examine the physical assets first. After all, they’re visible, expensive, and seem like the obvious culprit. I remember visiting a automotive parts manufacturer in Michigan where the plant manager proudly showed me their new $2 million injection molding machine.

“This baby can produce 500 parts per hour,” he said, patting the massive equipment. “But somehow we’re still falling behind on orders.”

The real problem? Their 15-year-old ERP system couldn’t communicate with the machine’s modern sensors, creating a data black hole that left operators flying blind.

Not long ago, I visited a mid-sized automotive components plant in the Southeast. During a walkthrough with their operations team, I noticed a familiar pattern: decades-old PLCs running production lines, a 2010-era ERP handling inventory and purchasing, and a new cloud-based quality system… none of them connected.

The IT Iceberg Effect

Most manufacturing IT problems are like icebergs; what you see on the surface is just a fraction of the real issue. Here’s what typically lies beneath:

- Disconnected systems that don’t talk to each other

- Manual data entry that introduces errors and delays

- Legacy software that can’t handle modern production demands

- Inadequate cybersecurity creates operational vulnerabilities

- Poor data quality leads to bad decision-making

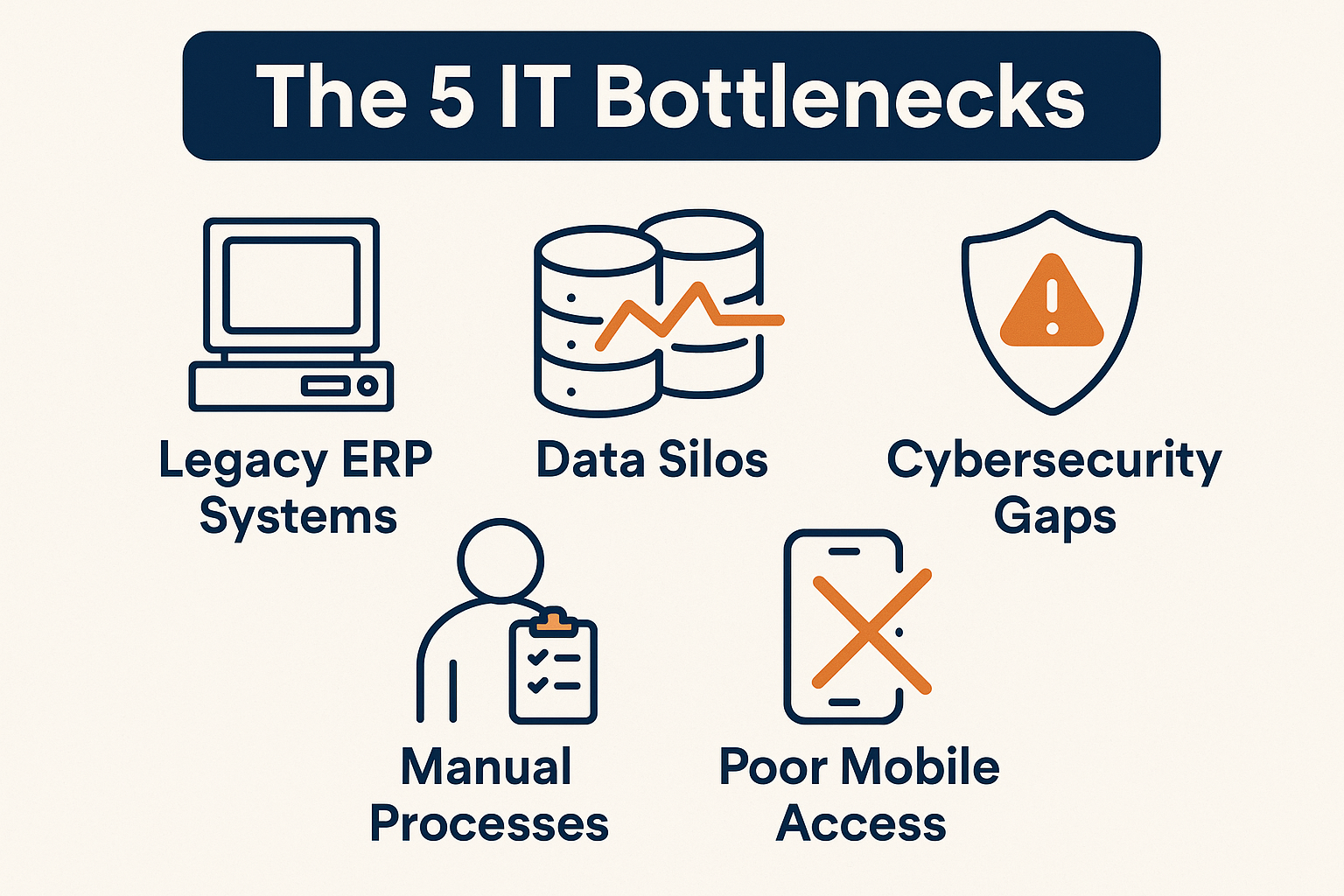

The Five IT Bottlenecks Strangling Your Manufacturing Operation

1. Legacy ERP Systems That Can’t Keep Up

The Problem: Your ERP system was cutting-edge… in 2005. Now it’s the digital equivalent of trying to run a Formula 1 race with a horse and buggy.

Why It Matters: Legacy ERP systems create cascading problems:

- Slow processing times that delay critical decisions

- Limited integration capabilities with modern equipment

- Poor mobile access that leaves field workers disconnected

- Inadequate reporting that hides operational insights

Real-World Impact: A textile manufacturer I worked with was losing $30,000 per week because their old ERP couldn’t process rush orders fast enough. By the time the system updated inventory levels, materials were already allocated elsewhere.

The Solution:

- Audit your current ERP capabilities against modern manufacturing needs

- Plan a phased modernization approach to minimize disruption

- Prioritize cloud-based solutions for scalability and remote access

- Ensure new systems integrate with existing equipment and workflows

2. Data Silos That Create Information Islands

The Problem: Your production data lives in one system, quality data in another, inventory in a third, and maintenance in a fourth. It’s like having a conversation where everyone speaks a different language.

Why It Matters: Data silos prevent you from seeing the complete picture of your operations. You might know that Machine A is running at 85% efficiency, but you don’t know it’s because the quality system flagged materials that the production system never received notification about.

The Numbers Don’t Lie:

- 73% of manufacturers struggle with data integration

- Companies with integrated data systems are 5x more likely to make decisions quickly

- Poor data integration costs the average manufacturer $15 million annually

The Solution:

- Implement a centralized data platform that connects all systems

- Establish data governance protocols to ensure consistency

- Use APIs and middleware to enable real-time data sharing

- Create unified dashboards that provide holistic operational views

3. Cybersecurity Gaps That Threaten Everything

The Problem: Manufacturing has become the #1 target for cyberattacks, yet many facilities still treat cybersecurity as an afterthought.

Why It Matters: A single cyberattack can bring your entire operation to a halt. In 2021, a ransomware attack on Colonial Pipeline disrupted fuel supplies across the Eastern United States for six days. For manufacturers, the stakes are equally high.

Scary Statistics:

- Manufacturing cyberattacks increased by 87% in 2024

- Average downtime from a manufacturing cyberattack: 23 days

- Average cost of a manufacturing data breach: $4.99 million

The Solution:

- Segment your operational technology (OT) networks from IT networks

- Implement zero-trust security protocols for all system access

- Regular security audits and penetration testing to identify vulnerabilities

- Employee training programs to prevent social engineering attacks

4. Manual Processes Disguised as Digital Solutions

The Problem: You’ve digitized your processes, but humans are still the weak link. Workers manually enter data from one system into another, creating bottlenecks and errors.

Why It Matters: Manual processes don’t scale. As production increases, these bottlenecks become more pronounced. Plus, manual data entry has an error rate of 1-3%, which compounds across multiple touchpoints.

Common Manual Bottlenecks:

- Operators manually logging production data

- Quality inspectors entering results into spreadsheets

- Maintenance teams using paper-based work orders

- Inventory counts are done with clipboards and calculators

The Solution:

- Automate data capture using sensors, scanners, and IoT devices

- Implement digital workflows that eliminate paper-based processes

- Use mobile apps that integrate directly with your systems

- Deploy predictive analytics to automate routine decisions

Ready to Eliminate Your IT Bottlenecks?

Don’t let outdated IT infrastructure limit your manufacturing potential.

Our manufacturing IT specialists have helped companies like yours unlock millions in productivity gains by modernizing their digital infrastructure from ERP upgrades to cybersecurity hardening. We know exactly where manufacturers get stuck and how to get them unstuck.

🚀 Ready to Fix Your IT Challenges?

Don’t wait until downtime or a cyberattack costs you thousands. Schedule your FREE Manufacturing IT Assessment today and take the first step toward a more efficient, secure, and scalable operation.

📅 Book a Schedule Now5. Poor Mobile and Remote Access Capabilities

The Problem: Your workforce is mobile, but your IT infrastructure isn’t. Technicians, supervisors, and managers need real-time access to systems and data, regardless of location.

Why It Matters: In today’s manufacturing environment, decisions happen on the shop floor, not in the office. When your team can’t access critical information quickly, production suffers.

Mobile Access Challenges:

- Supervisors can’t approve work orders from the production floor

- Maintenance teams can’t access equipment manuals and schematics

- Quality inspectors can’t immediately log findings and trigger alerts

- Management can’t monitor KPIs in real-time

The Solution:

Deploy mobile-first applications for critical workflows

Ensure robust Wi-Fi coverage throughout your facility

Implement role-based mobile dashboards for different user types

Enable offline capabilities for areas with connectivity issues

The Real Cost of IT Bottlenecks in Manufacturing

Financial Impact

Let me share some numbers that might surprise you. A recent study by McKinsey found that manufacturers with modern, integrated IT systems achieve:

- 25-40% improvement in overall equipment effectiveness (OEE)

- 20-30% reduction in maintenance costs

- 15-25% decrease in inventory carrying costs

- 30-50% faster time-to-market for new products

For a mid-sized manufacturer with $100 million in annual revenue, these improvements translate to $8-15 million in additional profit annually.

Operational Impact

Beyond the financial metrics, IT bottlenecks create operational headaches that compound over time:

Quality Issues:

- Delayed detection of quality problems

- Inconsistent quality data across shifts

- Difficulty tracing defects to root causes

Inventory Problems:

- Overstock of slow-moving materials

- Stockouts of critical components

- Poor visibility into supply chain disruptions

Maintenance Challenges:

- Reactive instead of predictive maintenance

- Longer equipment downtime

- Higher maintenance costs

Competitive Disadvantage

Perhaps most importantly, IT bottlenecks put you at a competitive disadvantage. While you’re struggling with manual processes and disconnected systems, your competitors are leveraging:

- Real-time production optimization

- Predictive quality control

- Automated inventory management

- AI-driven demand forecasting

How to Identify Your IT Bottlenecks

The Manufacturing IT Health Check

Not sure where your bottlenecks are? Here’s a simple assessment you can do right now:

Data Flow Assessment:

- Map how information flows from order to delivery

- Identify every manual handoff or data re-entry point

- Calculate the time delay at each step

- Look for places where the same data is entered multiple times

System Integration Test:

- Try to generate a real-time report that includes data from 3+ systems

- Note how long it takes and how many manual steps are required

- Check if the data is consistent across all systems

- Identify any “black holes” where data disappears

Mobile Access Audit:

- Try to access critical information from your phone while on the shop floor

- Test key workflows like approving work orders or checking inventory

- Note areas with poor connectivity or slow system response

- Ask frontline workers about their biggest mobile access frustrations

Warning Signs Your IT Infrastructure Is the Bottleneck

Red Flags to Watch For:

- Employees regularly complain about “slow systems”

- You can’t get real-time visibility into production status

- Quality issues are discovered hours or days after they occur

- Inventory counts don’t match system records

- You rely on spreadsheets for critical business processes

- System downtime regularly impacts production

- You can’t quickly respond to rush orders or changes

- Cybersecurity incidents have occurred in the past year

The Strategic Approach to Fixing IT Bottlenecks

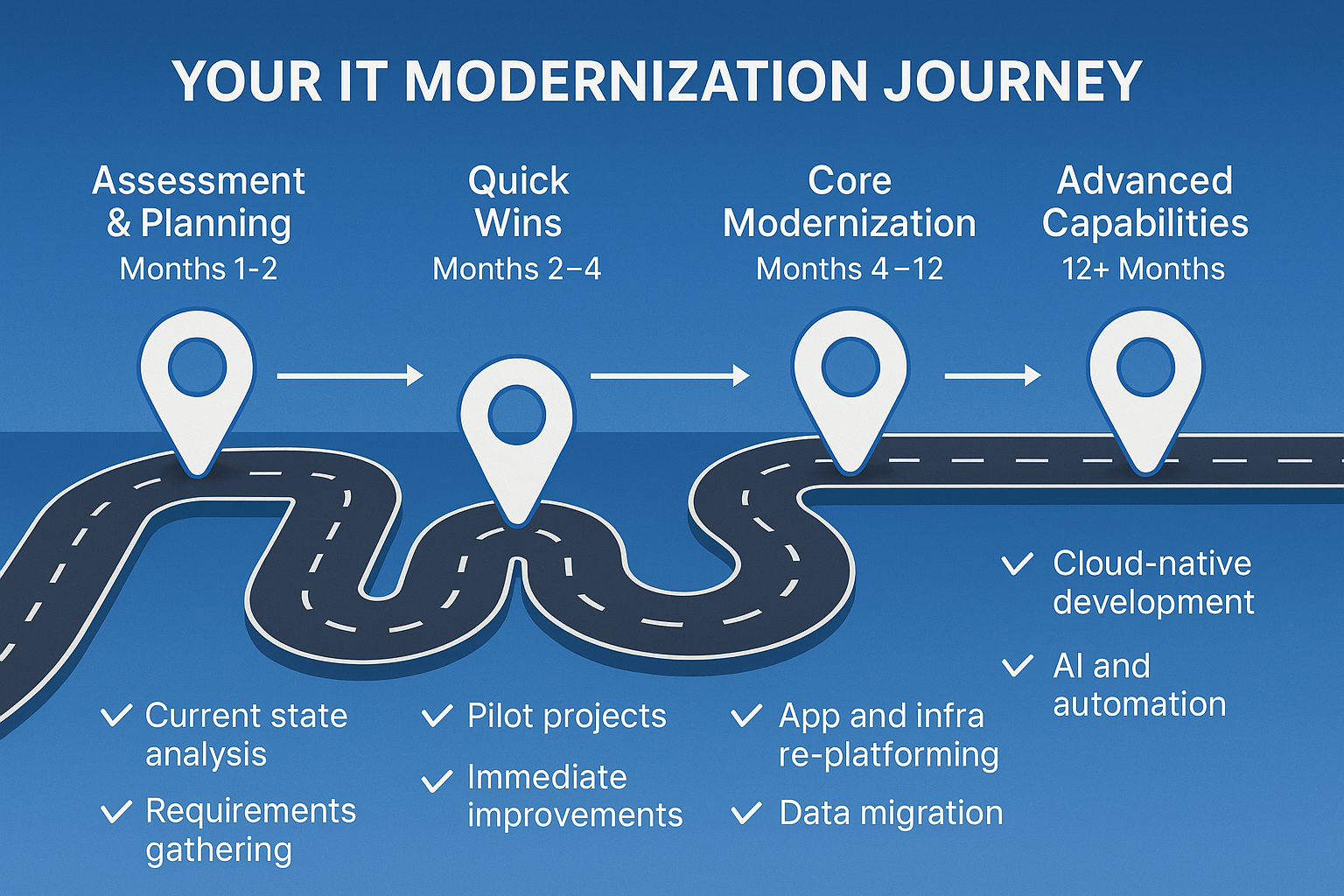

Phase 1: Assessment and Planning (Months 1-2)

Comprehensive IT Audit:

- Document all current systems and their capabilities

- Map data flows and integration points

- Identify security vulnerabilities

- Assess mobile and remote access needs

- Calculate the cost of current inefficiencies

Stakeholder Alignment:

- Get buy-in from operations, finance, and executive teams

- Establish clear ROI expectations

- Define success metrics and timelines

- Allocate budget and resources

Phase 2: Quick Wins (Months 2-4)

Low-Hanging Fruit:

- Eliminate obvious manual processes

- Improve Wi-Fi coverage in critical areas

- Deploy mobile apps for common workflows

- Implement basic cybersecurity measures

- Create automated reports for key metrics

Early ROI:

These quick wins often pay for themselves within 3-6 months and build momentum for larger initiatives.

Phase 3: Core System Modernization (Months 4-12)

Strategic Upgrades:

- ERP system modernization or replacement

- Integration platform implementation

- Advanced cybersecurity deployment

- IoT sensor network installation

- Predictive analytics capabilities

Change Management:

- Comprehensive user training programs

- Phased rollout to minimize disruption

- Continuous support and optimization

- Performance monitoring and adjustment

Phase 4: Advanced Capabilities (Months 12+)

Future-Ready Features:

- Artificial intelligence and machine learning

- Advanced predictive maintenance

- Supply chain optimization

- Real-time quality control

- Automated decision-making

Case Study: How One Manufacturer Eliminated Their IT Bottleneck

The Challenge

A $75M automotive supplier faced chronic delivery delays despite modern equipment. The real culprit wasn’t the machines, but a 12-year-old ERP system that couldn’t keep up with production volume.

Specific Problems:

- Order processing took 2-3 days instead of hours

- Inventory accuracy was only 65%

- Quality data was manually entered, causing delays

- No real-time visibility into production status

- Cybersecurity vulnerabilities exposed them to risk

The Solution

Working with AlphaCIS, they implemented a comprehensive IT modernization program:

Phase 1 (Quick Wins):

- Deployed mobile apps for shop floor data entry

- Implemented automated inventory scanning

- Upgraded cybersecurity protocols

- Created real-time production dashboards

Phase 2 (Core Modernization):

- Migrated to a cloud-based ERP system

- Integrated all production equipment with the new system

- Implemented predictive maintenance capabilities

- Deployed advanced quality control workflows

The Results

Within 6 months:

- Order processing time reduced from 2-3 days to 4 hours

- Inventory accuracy improved to 98%

- Overall equipment effectiveness (OEE) increased by 32%

- Quality defects decreased by 45%

- Cybersecurity posture strengthened significantly

Financial Impact:

- Annual cost savings: $3.2 million

- Revenue increase from improved delivery performance: $4.8 million

- Total ROI: 340% in the first year

Operational Transformation:

The company went from being a reactive, firefighting organization to a proactive, data-driven manufacturer. They now have real-time visibility into every aspect of their operation and can quickly respond to changes in demand or supply chain disruptions.

The Technology Stack for Modern Manufacturing

Core Infrastructure Components

Enterprise Resource Planning (ERP):

- Cloud-based for scalability and remote access

- Real-time processing capabilities

- Mobile-friendly interface

- Strong integration capabilities

- Industry-specific functionality

Manufacturing Execution System (MES):

- Real-time production monitoring

- Quality management integration

- Work order management

- Performance analytics

- Compliance tracking

Customer Relationship Management (CRM):

- Order management and tracking

- Customer communication tools

- Sales pipeline management

- Service and support integration

- Performance reporting

Integration and Analytics Layer

Integration Platform:

- API management

- Data transformation capabilities

- Real-time synchronization

- Error handling and monitoring

- Scalable architecture

Analytics and Business Intelligence:

- Real-time dashboards

- Predictive analytics

- Custom reporting tools

- Data visualization

- Mobile accessibility

Security and Infrastructure

Cybersecurity Framework:

- Network segmentation

- Multi-factor authentication

- Endpoint protection

- Security monitoring

- Incident response procedures

Cloud Infrastructure:

- Scalable computing resources

- Reliable data backup and recovery

- Geographic redundancy

- Performance optimization

- Cost management tools

Building Your IT Modernization Business Case

Calculating ROI for IT Investments

Cost Categories to Include:

Current State Costs:

- Lost productivity from system delays

- Manual labor for data entry and reconciliation

- Quality issues and rework

- Inventory carrying costs

- Cybersecurity incident response

- System maintenance and support

Future State Benefits:

- Increased throughput and efficiency

- Reduced labor costs

- Improved quality and reduced waste

- Optimized inventory levels

- Reduced cybersecurity risk

- Lower IT maintenance costs

Sample ROI Calculation

For a $50 million manufacturer:

Current Annual Costs:

- Lost productivity: $2.1 million

- Manual processes: $800,000

- Quality issues: $600,000

- Excess inventory: $1.2 million

Total: $4.7 million

IT Modernization Investment:

- Software and licenses: $500,000

- Implementation services: $300,000

- Training and change management: $100,000

Total: $900,000

Annual Benefits:

- 60% reduction in identified costs: $2.8 million

- Net Annual Benefit: $2.8 million

- ROI: 311% in Year 1

Presenting to Leadership

Key Messages for Executives:

- Competitive Advantage: “Our competitors are already leveraging these technologies.”

- Risk Mitigation: “Our current systems expose us to significant cybersecurity and operational risks.”

- Growth Enablement: “These investments will support our growth plans without proportional increases in overhead.”

- Customer Satisfaction: “Improved systems will help us deliver better service and quality to our customers.”

Implementation Best Practices

Change Management Strategies

Communication is Key:

- Explain the “why” behind changes

- Share success stories and early wins

- Address concerns and resistance openly

- Provide regular updates on progress

Training and Support:

- Comprehensive training programs for all users

- Hands-on practice in safe environments

- Ongoing support during transition periods

- Super-user programs to provide peer support

Phased Rollout:

- Start with pilot groups or departments

- Learn and adjust based on feedback

- Gradually expand to a full organization

- Maintain parallel systems during transition

Common Implementation Pitfalls

Pitfall #1: Underestimating Change Management

Solution: Allocate 20-30% of the project budget to change management activities

Pitfall #2: Trying to Do Everything at Once

Solution: Focus on high-impact, low-risk improvements first

Pitfall #3: Ignoring Data Quality

Solution: Clean and standardize data before migration

Pitfall #4: Inadequate Testing

Solution: Comprehensive testing in production-like environments

Pitfall #5: Poor Vendor Selection

Solution: Thorough evaluation process with reference checks

The Future of Manufacturing IT

Emerging Technologies to Watch

Artificial Intelligence and Machine Learning:

- Predictive quality control

- Demand forecasting

- Automated scheduling optimization

- Intelligent maintenance planning

Internet of Things (IoT):

- Comprehensive equipment monitoring

- Environmental condition tracking

- Asset location and utilization

- Energy consumption optimization

Edge Computing:

- Real-time processing at the point of production

- Reduced latency for critical applications

- Improved reliability and resilience

- Enhanced data security

Digital Twins:

- Virtual replicas of physical assets

- Simulation and optimization capabilities

- Predictive modeling

- Remote monitoring and control

Preparing for Industry 4.0

Building a Future-Ready Foundation:

- Invest in Scalable Infrastructure: Choose solutions that can grow with your business

- Develop Data Capabilities: Focus on data quality, integration, and analytics

- Build Internal Expertise: Train your team on new technologies and processes

- Partner with Experts: Work with vendors and consultants who understand manufacturing

- Stay Informed: Keep up with industry trends and best practices

Taking Action: Your Next Steps

Immediate Actions (This Week)

- Conduct the IT Health Check outlined earlier in this article

- Document your top 3 IT pain points and their business impact

- Calculate the cost of your current inefficiencies

- Identify key stakeholders who need to be involved in IT modernization decisions

Short-Term Actions (Next 30 Days)

- Perform a comprehensive IT audit with internal or external resources

- Research potential solutions for your highest-priority issues

- Develop a preliminary business case for IT modernization

- Schedule discussions with key stakeholders about IT priorities

Long-Term Actions (Next 90 Days)

- Create a detailed IT modernization roadmap with timelines and budgets

- Evaluate and select technology partners who understand manufacturing

- Secure executive approval for your modernization initiative

- Begin implementation with quick wins and pilot projects

Interactive Manufacturing IT Bottleneck Assessment

🏭 Manufacturing IT Bottleneck Assessment

Discover where IT issues are limiting your manufacturing potential

🎯 Recommended Next Steps:

🚀 Ready to Fix Your IT Challenges?

Don’t wait until downtime or a cyberattack costs you thousands. Schedule your FREE Manufacturing IT Assessment today and take the first step toward a more efficient, secure, and scalable operation.

📅 Book a Schedule NowConclusion: Transform Your Manufacturing with Strategic IT Modernization

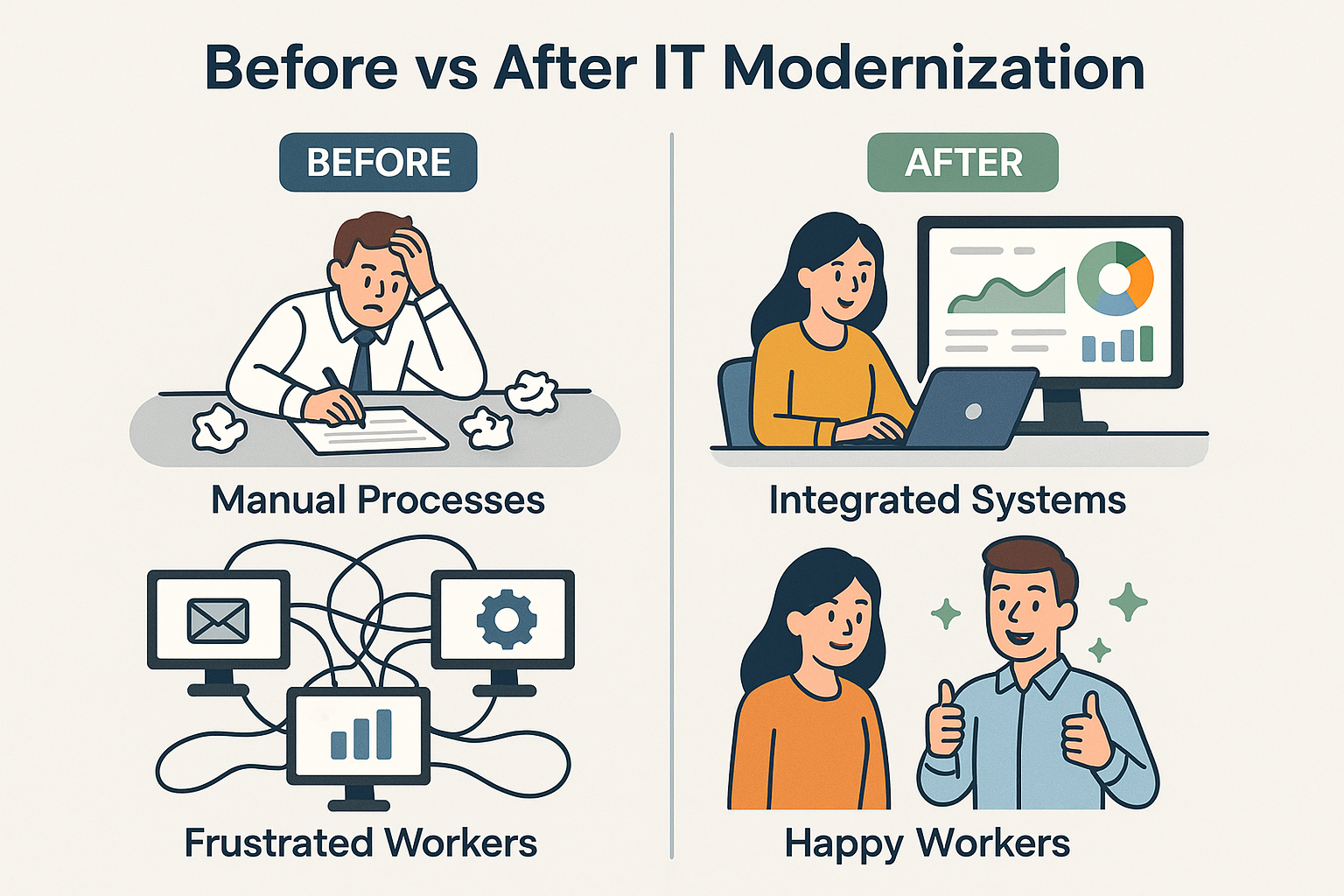

As we’ve explored throughout this article, every manufacturer has a bottleneck, and for most, it’s not the machine; it’s the IT infrastructure that’s supposed to support those machines. The evidence is overwhelming: companies that modernize their IT systems see dramatic improvements in productivity, quality, and profitability.

The manufacturers who thrive in 2025 and beyond won’t be those with the newest machines; they’ll be those with the smartest, most integrated digital infrastructure. While your competitors struggle with manual processes, data silos, and cybersecurity vulnerabilities, you can be leveraging real-time data, predictive analytics, and seamless automation to deliver superior results.

The Path Forward

The journey to eliminate your IT bottlenecks doesn’t have to be overwhelming. Start with the assessment tools and strategies outlined in this article. Identify your biggest pain points, calculate the cost of inaction, and build a compelling business case for change.

Remember: every day you delay IT modernization is another day your competitors gain ground. The manufacturers who act now will have a sustainable competitive advantage for years to come.

Your Next Steps

- Complete the IT Bottleneck Assessment above to understand your current state

- Calculate the ROI of addressing your top IT pain points

- Engage with IT modernization experts who understand manufacturing

- Start with quick wins that build momentum for larger initiatives

- Develop a comprehensive roadmap for long-term digital transformation

The technology exists today to eliminate your IT bottlenecks and unlock your manufacturing potential. The question isn’t whether you can afford to modernize your IT infrastructure but whether you can afford not to.

Ready to eliminate your IT bottlenecks and unlock your manufacturing potential? The future of your operation depends on the decisions you make today.

🚀 Ready to Fix Your IT Challenges?

Don’t wait until downtime or a cyberattack costs you thousands. Schedule your FREE Manufacturing IT Assessment today and take the first step toward a more efficient, secure, and scalable operation.

📅 Book a Schedule Now

Dmitriy Teplinskiy

I have worked in the IT industry for 15+ years. During this time I have consulted clients in accounting and finance, manufacturing, automotive and boating, retail and everything in between. My background is in Networking and Cybersecurity